High-performance vehicles need strong, precise parts. Automotive Injection Molds create lightweight, durable components. Expert Mold Makers ensure perfect designs. Every part must meet strict industry standards. Precision molding improves safety, efficiency, and aerodynamics.

Why Precision Molding is Essential for High-Performance Vehicles

1. Accuracy in Complex Designs

Every millimeter matters in performance cars. Automotive Injection Molds shape intricate parts. This ensures a perfect fit and function.

2. Lightweight Yet Strong Components

Weight affects speed and fuel efficiency. High-performance plastics replace metals. Mold Makers create durable, lightweight parts.

3. Heat and Pressure Resistance

Engines and braking systems generate heat. Plastic parts must withstand extreme temperatures. Precision molding ensures high resistance.

4. Cost-Effective Mass Production

Injection molding speeds up production. Molds last for thousands of cycles. Mold Makers design molds for high efficiency.

5. Consistent Quality and Durability

Performance parts must perform under stress. Automotive Injection Molds ensure uniformity. This reduces defects and enhances longevity.

Key High-Performance Vehicle Parts Made with Injection Molding

1. Engine Covers and Housings

- Protect internal components

- Made from heat-resistant plastics

- Reduce engine noise

2. Air Intake Manifolds

- Improve airflow and fuel efficiency

- Require precise molding for performance

- Must withstand high temperatures

3. Brake System Components

- ABS sensor housings need precision

- Heat-resistant plastics improve safety

- Lightweight materials enhance performance

4. Fuel System Components

- Fuel caps, filters, and lines use injection molding

- Must resist corrosion and fuel exposure

- Mold Makers ensure perfect sealing

5. Dashboard and Interior Panels

- Require smooth, high-quality finishes

- Lightweight and durable

- Must resist heat and UV exposure

6. Aerodynamic Body Panels

- Reduce drag and increase speed

- Made with strong, lightweight plastics

- Automotive Injection Molds ensure precise shapes

7. Structural Reinforcements

- Enhance vehicle stability

- Made from fiber-reinforced plastics

- Reduce weight without losing strength

8. High-Precision Gears and Bushings

- Require exact dimensions for efficiency

- Used in steering and transmission systems

- Molded from wear-resistant plastics

9. Cooling System Components

- Fan housings and radiator parts need precision

- Must handle high temperatures and vibrations

- Mold Makers ensure long-lasting durability

10. Battery Housings for Electric Vehicles

- Protect high-voltage battery systems

- Require impact-resistant materials

- Must be lightweight for efficiency

Materials Used in High-Performance Injection Molding

1. Polyphenylene Sulfide (PPS)

- High heat resistance

- Used in fuel and engine parts

- Strong and chemically stable

2. Polyether Ether Ketone (PEEK)

- Extremely strong and lightweight

- Used in transmission components

- Resists high pressure and temperature

3. Carbon Fiber Reinforced Polymers

- High strength-to-weight ratio

- Used in body panels and structural parts

- Improves aerodynamics

4. Acrylonitrile Butadiene Styrene (ABS)

- Durable and impact-resistant

- Used in interior and exterior trims

- Provides a smooth surface finish

5. Thermoplastic Polyurethane (TPU)

- Flexible yet tough

- Used in seals and bushings

- Resists wear and tear

How Mold Makers Ensure Precision in High-Performance Parts

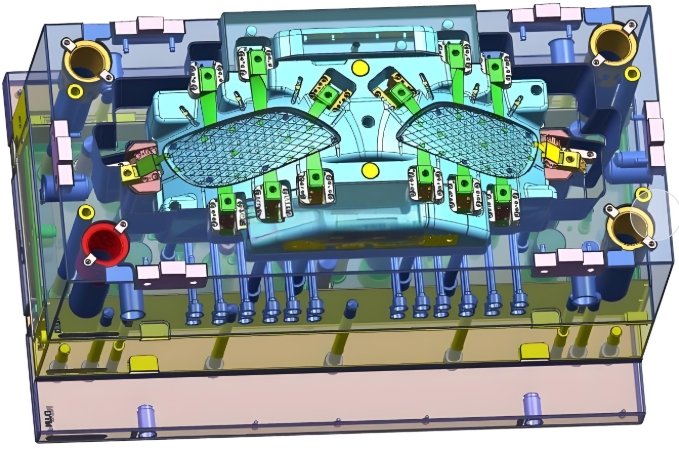

1. Advanced CAD Design for Mold Creation

Mold Makers use computer-aided design (CAD). They develop highly detailed molds. This ensures accuracy and efficiency.

2. CNC Machining for Mold Production

CNC machines cut molds with extreme precision. This reduces errors. Automotive Injection Molds require perfect dimensions.

3. Testing and Quality Control

Each mold undergoes testing. Mold Makers check for defects. This guarantees high-quality final products.

4. Multi-Cavity Molds for Faster Production

Multiple parts can be produced at once. This speeds up manufacturing. Automotive Injection Molds improve efficiency.

Advanced Techniques in High-Performance Injection Molding

1. Gas-Assisted Injection Molding

- Reduces material use

- Creates lightweight, hollow sections

- Used in dashboard components

2. Overmolding for Multi-Material Parts

- Combines different materials in one mold

- Improves grip and durability

- Used in steering wheels and control panels

3. Insert Molding for Stronger Parts

- Embeds metal parts in plastic

- Increases structural integrity

- Used in fuel system components

4. High-Precision Micro Molding

- Creates tiny, intricate parts

- Used in sensors and electronic housings

- Ensures perfect accuracy

5. In-Mold Labeling (IML) and Decoration

- Adds designs directly in the mold

- Prevents fading and peeling

- Used in dashboard panels and trims

Trends in High-Performance Automotive Injection Molds

1. Lightweight Materials for Speed Efficiency

- Reducing weight increases performance

- High-strength plastics replace metals

- Mold Makers innovate for weight reduction

2. Integration of Smart Features

- Sensors embedded in plastic parts

- Improves vehicle diagnostics

- Enhances safety and control

3. Sustainable and Recycled Materials

- Reduces waste and environmental impact

- New bio-based plastics gain popularity

- Automotive Injection Molds adapt to green technologies

4. 3D Printing for Rapid Mold Prototyping

- Speeds up development

- Reduces cost for new designs

- Helps in customized performance parts

Challenges in Precision Injection Molding

1. Achieving High-Temperature Resistance

- Engine parts face extreme heat

- Plastics must not degrade

- Mold Makers select heat-resistant materials

2. Meeting Strict Performance Standards

- Every part must meet safety regulations

- Any defect can affect vehicle efficiency

- Automotive Injection Molds must be flawless

3. Maintaining Cost-Effective Production

- High-performance materials can be expensive

- Mold Makers optimize mold longevity

- Reduces manufacturing costs

4. Balancing Weight and Strength

- Parts must be lightweight but strong

- Automotive Injection Molds ensure perfect material balance

- Improves durability and efficiency

Future of Automotive Injection Molds in High-Performance Vehicles

1. AI-Optimized Molding Processes

- AI predicts and corrects molding defects

- Improves efficiency and speed

2. Self-Healing Plastics

- New materials repair minor damages

- Increases part lifespan

3. Fully Automated Injection Molding Plants

- Robotics enhance speed and precision

- Reduces human errors and costs

4. Eco-Friendly Manufacturing Innovations

- New sustainable plastics replace traditional materials

- Lowers environmental impact

Automotive Injection Molds shape the future of high-performance vehicles. Precision molding ensures strength, efficiency, and durability. Expert Mold Makers design advanced molds for exact specifications. Innovations in materials and processes continue to push boundaries. The future of performance cars depends on high-quality injection molding.