Smart devices dominate our lives. They demand innovative designs. Rapid Prototyping meets these demands. It enables quick, efficient product creation. Working with a skilled Injection Mould Company ensures the best results. This article explains why Rapid Prototyping is vital for smart devices.

Why Smart Devices Need Rapid Prototyping

Fast Development

Smart device markets evolve quickly. Prototypes must match speed. Rapid Prototyping delivers models rapidly.

Testing and Improvement

Prototypes test functionality. This process identifies flaws early. Adjustments ensure final products excel.

Market Readiness

Products reach the market faster. This gives businesses a competitive edge.

Key Benefits for Smart Devices

Accurate Designs

Rapid Prototyping uses CAD for precision. Designs match real-world applications.

Customization

Smart devices need unique features. Prototyping allows tailored solutions.

Cost Efficiency

Prototypes reduce errors. This saves money during production.

Material Testing

Prototypes test materials for durability. This ensures high-quality products.

How an Injection Mould Company Helps

Expert Guidance

They refine designs for manufacturability.

Material Selection

They suggest suitable materials for smart devices.

Scalability

They streamline transitions from prototypes to production.

Problem Solving

They troubleshoot design challenges effectively.

Applications in Smart Devices

Wearables

Smartwatches and fitness trackers benefit greatly. Prototyping ensures comfort and functionality.

IoT Devices

Prototypes validate connectivity and usability.

Smart Home Gadgets

Thermostats and cameras are optimized through prototyping.

Smartphones

Designs are tested for durability and aesthetics.

Healthcare Devices

Prototyping ensures reliability in smart medical tools.

The Role of Technology in Rapid Prototyping

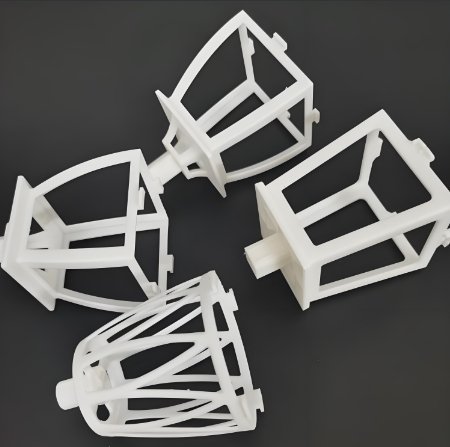

3D Printing

Creates complex prototypes quickly.

CNC Machining

Provides precise parts for testing.

Laser Cutting

Shapes materials with extreme accuracy.

Additive Manufacturing

Builds lightweight, durable prototypes.

Common Challenges in Prototyping

Tight Deadlines

The need for speed adds pressure.

Complex Designs

Intricate models require advanced tools.

Material Compatibility

Finding the right material can be tricky.

Iterative Processes

Multiple adjustments may delay progress.

How to Overcome Challenges

Collaborate with Experts

Partner with a reputable Injection Mould Company.

Simplify Initial Designs

Focus on core features first.

Test Frequently

Check prototypes at each stage.

Invest in Technology

Use the latest tools for better efficiency.

Steps for Effective Rapid Prototyping

Step 1: Design Creation

CAD software develops detailed models.

Step 2: Prototype Development

Prototypes are built for testing.

Step 3: Material Testing

Prototypes evaluate material strength.

Step 4: Functional Testing

Designs undergo real-world tests.

Step 5: Production Scaling

Approved designs transition to mass production.

Trends in Smart Device Prototyping

AI Integration

AI tools refine designs faster.

Advanced Materials

Innovative materials improve durability.

Sustainability

Eco-friendly materials become more popular.

Miniaturization

Prototyping enables smaller, smarter devices.

Case Study: Smart Thermostats

A company wanted to develop a new thermostat.

Problem

Their existing designs lacked precision.

Solution

They used Rapid Prototyping to test and refine.

Results

The product launched 30% faster. Customers praised its functionality.

Why Choose an Injection Mould Company?

Expertise

They optimize designs for manufacturing.

Reliability

They ensure consistency in prototypes and production.

Support

They guide you through every step.

Efficiency

They save time and resources.

Smart devices need precision and speed. Rapid Prototyping ensures both. Working with an experienced Injection Mould Company makes the process smoother. This partnership enhances designs and accelerates production. Invest in Rapid Prototyping to stay ahead in smart device innovation.

Start prototyping smarter today!