Automotive interiors require precision. Automotive injection molds create high-quality parts. A skilled mold maker ensures durability and style. Technology enhances efficiency.

The Role of Injection Molds in Interior Manufacturing

1. High-Quality Dashboard Components

Dashboards must be strong. Automotive injection molds shape perfect designs. A mold maker ensures smooth finishes.

2. Durable Door Panels

Door panels need durability. Automotive injection molds provide consistency. A mold maker controls thickness and texture.

3. Precise Center Consoles

Center consoles require detail. Automotive injection molds create seamless designs. A mold maker ensures accuracy.

4. Comfortable Armrests

Armrests need soft materials. Automotive injection molds handle different textures. A mold maker ensures ergonomic designs.

Advanced Technologies in Automotive Interior Mold Making

1. 3D Printing for Prototyping

3D printing speeds up development. Automotive injection molds get tested early. A mold maker improves accuracy.

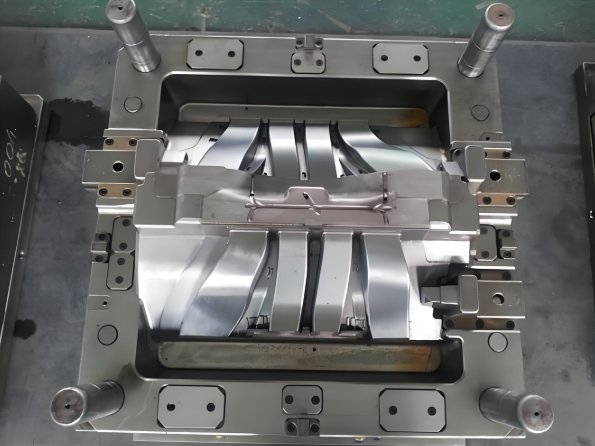

2. CNC Machining for High Precision

CNC machining enhances precision. Automotive injection molds require exact dimensions. A mold maker programs machines for accuracy.

3. Multi-Cavity Molds for Mass Production

Multi-cavity molds increase output. Automotive injection molds reduce production time. A mold maker ensures efficiency.

4. AI-Powered Quality Control

AI detects defects. Automotive injection molds require flawless finishes. A mold maker uses AI for inspections.

Materials for Automotive Interior Molds

1. High-Performance Plastics

Plastics must be durable. Automotive injection molds use heat-resistant materials. A mold maker selects premium resins.

2. Soft-Touch Surfaces

Luxury interiors need soft materials. Automotive injection molds create textured surfaces. A mold maker ensures comfort.

3. Recycled Materials for Sustainability

Eco-friendly solutions are key. Automotive injection molds use recycled plastics. A mold maker supports sustainability.

4. Composite Materials for Strength

Composites improve durability. Automotive injection molds create long-lasting parts. A mold maker enhances strength.

Enhancing Aesthetics with Injection Molds

1. Glossy and Matte Finishes

Different finishes improve style. Automotive injection molds create sleek looks. A mold maker controls surface textures.

2. Seamless Integration of Features

Precision ensures smooth designs. Automotive injection molds eliminate gaps. A mold maker focuses on flawless details.

3. Custom Colors and Patterns

Injection molding allows customization. Automotive injection molds offer various colors. A mold maker matches brand aesthetics.

4. Engraved and Embossed Details

Details add sophistication. Automotive injection molds create unique textures. A mold maker enhances branding.

Innovations in Mold Cooling Systems

1. Conformal Cooling for Faster Production

Cooling reduces cycle times. Automotive injection molds need even temperature control. A mold maker prevents warping.

2. Water and Oil-Based Cooling Systems

Different methods enhance cooling. Automotive injection molds require proper heat management. A mold maker selects the best system.

3. Smart Temperature Sensors

Sensors improve efficiency. Automotive injection molds benefit from live monitoring. A mold maker adjusts conditions instantly.

4. Heat-Resistant Coatings

Coatings prevent damage. Automotive injection molds last longer with heat protection. A mold maker extends mold life.

Cost-Efficient Production with Modern Molds

1. Automated Injection Molding Systems

Automation reduces costs. Automotive injection molds improve efficiency. A mold maker cuts waste and labor expenses.

2. Low Scrap Rates

Precision reduces waste. Automotive injection molds ensure minimal defects. A mold maker optimizes material use.

3. Fast Cycle Times

Speed boosts production. Automotive injection molds complete parts quickly. A mold maker maximizes output.

4. Minimal Maintenance Requirements

Durable molds need less maintenance. Automotive injection molds last longer with better materials. A mold maker reduces downtime.

Future Trends in Automotive Interior Molds

1. Smart Molds with IoT Connectivity

IoT enhances performance. Automotive injection molds will feature real-time monitoring. A mold maker will adjust settings remotely.

2. AI-Optimized Mold Designs

AI predicts best designs. Automotive injection molds will be more precise. A mold maker will reduce errors.

3. Eco-Friendly Bio-Based Materials

Sustainability is growing. Automotive injection molds will use biodegradable plastics. A mold maker will support green initiatives.

4. Ultra-Lightweight Molded Parts

Weight reduction improves efficiency. Automotive injection molds will create lighter components. A mold maker will focus on fuel economy.

Technology is revolutionizing interiors. Automotive injection molds enhance durability and aesthetics. A skilled mold maker ensures precision. Future innovations promise even better results.