Vehicles require precision in every part. Automotive injection molds create these parts with accuracy. These molds shape plastics into durable components. A skilled mold maker ensures high quality. Every part must fit perfectly in the assembly line.

Why Automotive Injection Molds Are Essential

Manufacturing vehicles requires speed and consistency. Automotive injection molds allow mass production with minimal errors. They reduce material waste. They ensure every part meets strict industry standards. Without molds, assembly lines slow down. A professional mold maker prevents such issues.

Key Automotive Components Made with Injection Molds

1. Interior Components

Dashboards, door panels, and consoles come from automotive injection molds. They need smooth finishes and durability.

2. Exterior Components

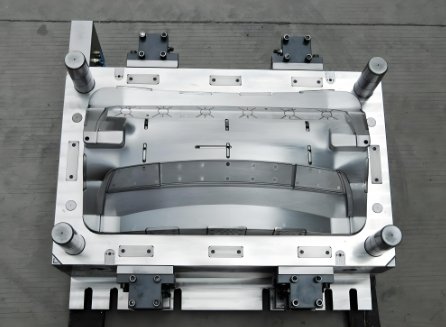

Bumpers, grilles, and side mirrors require strong materials. Mold makers design molds that ensure impact resistance.

3. Engine and Under-the-Hood Parts

Battery casings, fluid reservoirs, and air ducts must withstand high temperatures. Injection molding makes them lightweight yet strong.

4. Lighting Components

Headlight and taillight housings need precision. Automotive injection molds shape them for clarity and durability.

The Role of a Mold Maker in Automotive Manufacturing

A mold maker plays a crucial role in creating perfect molds. Every step must be precise. Even small errors cause defects.

1. Design and Engineering

Engineers create detailed 3D designs. The mold must match exact specifications.

2. Material Selection

Steel and aluminum are common mold materials. Steel molds last longer. Aluminum molds are cheaper for short runs.

3. CNC Machining

Machines cut mold parts with extreme accuracy. This ensures all components fit together perfectly.

4. Heat Treatment

This process strengthens the mold. It prevents wear and tear over time.

5. Polishing and Finishing

Molds require smooth surfaces. A mold maker polishes them to ensure perfect part production.

6. Testing and Quality Control

Molds undergo testing before mass production. Any defects must be corrected immediately.

Types of Automotive Injection Molds

1. Single-Cavity Molds

These molds produce one part at a time. They are ideal for large automotive components.

2. Multi-Cavity Molds

These molds create multiple identical parts in one cycle. They increase production efficiency.

3. Hot Runner Molds

These molds reduce material waste. They improve part quality and speed up production.

4. Cold Runner Molds

These are simpler and cheaper but produce more waste. They work well for lower-cost projects.

Challenges in Automotive Injection Molding

1. High Precision Demands

Automotive parts require strict tolerances. Even a small error causes defects.

2. Material Costs

Steel and aluminum are expensive. A mold maker must balance cost and durability.

3. Long Production Times

Molds take time to manufacture. Every step requires extreme accuracy.

4. Consistency in Large Production Runs

Each mold must create identical parts. Any variation causes assembly line issues.

Innovations in Automotive Injection Molds

1. 3D Printing for Prototyping

3D printing speeds up the design process. Engineers test designs before full production.

2. Advanced CNC Machining

Modern CNC machines cut with more precision. This improves mold accuracy and efficiency.

3. Automation in Mold Manufacturing

Robots now assist mold makers. Automation reduces human errors.

4. Sustainable Mold Materials

New eco-friendly materials reduce environmental impact. This helps manufacturers meet sustainability goals.

How Injection Molds Improve Vehicle Assembly Lines

1. Faster Production

Automotive injection molds speed up vehicle manufacturing. Mass production becomes more efficient.

2. Cost Efficiency

Molding reduces labor costs. It allows high-volume production with minimal waste.

3. High Part Quality

Precision molds ensure top-quality components. This reduces defects and recalls.

4. Customization for Different Vehicle Models

Molds adapt to different car designs. This allows flexibility in production.

The Future of Mold Makers in the Automotive Industry

The demand for automotive injection molds is increasing. Electric and hybrid vehicles require new mold designs. Lightweight materials are becoming standard. Automation is transforming mold manufacturing. A skilled mold maker must stay updated with new technologies.

Automotive injection molds are essential for modern vehicle production. They improve efficiency and precision in assembly lines. A skilled mold maker ensures durability and accuracy. The future of automotive injection molds is bright. Innovation continues to drive the industry forward.