Outsourcing medical injection molding has become a popular option for many companies. It offers potential benefits in terms of cost savings, efficiency, and expertise. However, there are also risks involved. Deciding whether to outsource your mold maker services requires careful consideration of both the advantages and disadvantages.

1. What is Medical Injection Molding?

1.1 Definition

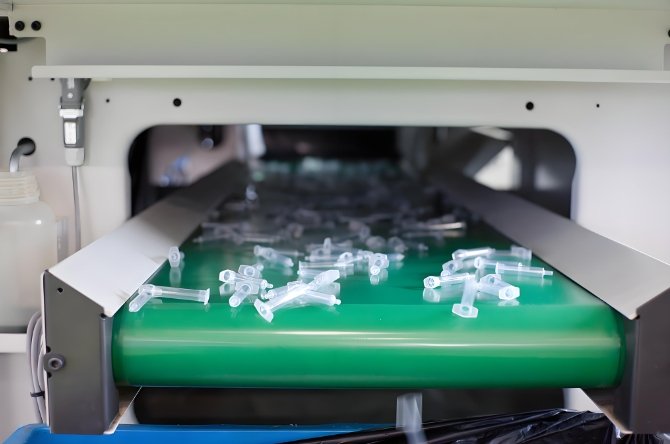

Medical injection molding is a manufacturing process used to produce medical components. It involves injecting molten material into a mold to create precise parts. These parts are essential in making devices, equipment, and packaging used in the medical industry.

1.2 Why It Matters

The medical industry demands high standards of quality and precision. This makes medical injection molding critical in the development of safe, reliable products. Companies must ensure they meet strict regulatory requirements.

2. What Does Outsourcing Mean?

2.1 Definition of Outsourcing

Outsourcing refers to hiring an external company to handle part of the manufacturing process. In the case of medical injection molding, this could mean contracting a third-party mold maker to produce your components.

2.2 Benefits of Outsourcing

Outsourcing offers several advantages, especially when managing complex manufacturing processes like injection molding.

3. Pros of Outsourcing Medical Injection Molding

3.1 Cost Savings

- Lower production costs: Outsourcing can significantly reduce manufacturing costs, especially for companies without large-scale facilities.

- Fewer overhead expenses: Outsourcing eliminates the need to invest in expensive machinery and facilities.

- Reduced labor costs: You won’t need to hire as many employees, saving on salaries and benefits.

3.2 Access to Expertise

- Experienced mold makers: Outsourcing gives you access to highly skilled professionals who specialize in medical injection molding.

- Advanced technology: Many external manufacturers have cutting-edge equipment and facilities.

- Quality control: Experts ensure that all products meet stringent medical industry standards.

3.3 Improved Efficiency

- Faster production: With outsourcing, your manufacturing process can be more streamlined.

- Focus on core business: Outsourcing allows your company to focus on research, marketing, and other critical areas.

- Reduced lead time: Professional manufacturers can meet deadlines faster due to their experience and equipment.

3.4 Flexibility

- Scalability: Outsourcing gives you the flexibility to scale production based on demand.

- Reduced risk: By outsourcing, you’re not tied to a single production method or location.

- Faster prototyping: Outsourcing companies can quickly test and modify prototypes, speeding up the product development process.

3.5 Compliance and Regulatory Expertise

- Regulation knowledge: Mold makers specializing in medical injection molding understand the strict regulations that apply to medical devices.

- FDA and ISO certifications: Many outsourcing companies are already certified, ensuring compliance with regulatory standards.

4. Cons of Outsourcing Medical Injection Molding

4.1 Loss of Control

- Less oversight: Outsourcing means you have less direct control over the production process.

- Communication challenges: Working with an external team may lead to misunderstandings, especially if the company is located in another region or country.

- Quality issues: Outsourcing may result in quality inconsistencies if the manufacturer doesn’t meet your standards.

4.2 Potential Delays

- Supply chain disruptions: Outsourcing increases the number of steps in the supply chain, which can cause delays.

- Production slowdowns: If the external manufacturer experiences any issues, it may take longer to resolve them.

- Time zone differences: Working with international suppliers can lead to time delays in communication and decision-making.

4.3 Intellectual Property Risks

- IP theft: Sharing your design with an external company could expose you to intellectual property theft.

- Loss of exclusivity: If the manufacturer works with other companies in your industry, they might share insights from your designs.

- Protection of designs: It’s critical to safeguard your designs through non-disclosure agreements and patents.

4.4 Communication Barriers

- Language differences: If outsourcing overseas, language barriers can cause confusion.

- Cultural differences: Different business practices or time expectations may lead to misunderstandings.

- Lack of transparency: You may not have full insight into the manufacturing process, making it harder to make informed decisions.

4.5 Quality Control Challenges

- Inconsistent quality: External manufacturers might not follow the exact specifications or quality controls you require.

- Regulatory challenges: Not all outsourcing companies meet the same strict regulatory standards, potentially compromising product safety.

- Monitoring difficulties: Keeping track of production quality remotely can be challenging.

5. How to Mitigate the Risks of Outsourcing

5.1 Choose a Trusted Partner

- Research suppliers: Look for outsourcing partners with proven experience in medical injection molding.

- Check certifications: Ensure they hold the necessary industry certifications like ISO and FDA approval.

- Ask for references: Speak to other clients who have worked with the supplier to get an idea of their reputation.

5.2 Sign Clear Contracts

- Non-disclosure agreements: Protect your intellectual property by using NDAs.

- Quality standards: Set clear quality control expectations in the contract.

- Timelines: Specify production deadlines and penalties for delays.

5.3 Regular Communication

- Frequent updates: Keep in close contact with the outsourced team to stay updated on progress.

- Video conferences: Use virtual meetings to discuss the project in real time.

- On-site visits: If possible, visit the supplier’s facility to ensure they meet your standards.

6. When Should You Outsource Medical Injection Molding?

6.1 When You Lack In-House Capabilities

Outsourcing makes sense if your company lacks the expertise, equipment, or facilities to handle medical injection molding effectively.

6.2 When You Need to Scale Quickly

If your production needs change rapidly, outsourcing provides the flexibility to scale production without significant investment.

6.3 When You Want to Focus on Core Activities

Outsourcing allows you to focus on activities like marketing, R&D, and sales while leaving the manufacturing process to experts.

Outsourcing medical injection molding has both advantages and disadvantages. It offers cost savings, expertise, and faster production, but also carries risks such as loss of control and communication challenges. By carefully choosing a reliable mold maker and setting clear expectations, you can minimize these risks and ensure the best outcomes for your business. Evaluate your company’s needs, capabilities, and goals to determine if outsourcing is the right choice for you.