Single-use medical products are essential in healthcare. They reduce contamination risks and improve patient safety. Medical injection molding helps produce these products quickly and efficiently. Mold makers design precise molds to ensure high-quality results.

Why Single-Use Medical Products Matter

1. Prevents Cross-Contamination

Disposable medical products eliminate the need for sterilization. This reduces infection risks.

2. Ensures Patient Safety

Sterile, single-use items lower the chance of spreading diseases.

3. Cost-Effective for Healthcare Facilities

Using disposable products removes the cost of cleaning and sterilization.

4. Convenient and Easy to Use

Single-use items are pre-sterilized and ready for immediate use.

5. Improves Efficiency in Hospitals

Medical staff can focus on patient care instead of sterilizing equipment.

Common Single-Use Medical Products Made with Injection Molding

1. Syringes and Needles

Hospitals use billions of syringes each year. Medical injection molding ensures each one meets strict safety standards.

2. IV Tubes and Connectors

IV tubes deliver medication and fluids. Molding ensures precise connections for leak-free performance.

3. Catheters

Disposable catheters prevent urinary tract infections. They must be smooth, flexible, and durable.

4. Blood Collection Tubes

Injection-molded tubes safely store blood samples. They require airtight seals and chemical resistance.

5. Respiratory Masks and Filters

Medical masks protect against airborne diseases. They must fit well and be breathable.

6. Surgical Instruments

Some forceps, clamps, and scissors are single-use. Molding ensures sharpness and precision.

7. Test Kits and Sample Containers

COVID-19 test kits and other diagnostic tools rely on precise molding.

8. Wound Care Products

Molded plastic applicators help apply dressings and ointments.

Materials Used in Medical Injection Molding for Disposable Products

1. Polypropylene (PP)

PP is lightweight, chemical-resistant, and cost-effective. It is used for syringes, IV components, and test tubes.

2. Polyethylene (PE)

PE is flexible and durable. It is used for tubing, catheters, and medical pouches.

3. Polycarbonate (PC)

PC is strong and transparent. It is used for blood collection tubes and surgical instrument handles.

4. Polystyrene (PS)

PS is clear and rigid. It is used for petri dishes and lab equipment.

5. Thermoplastic Elastomers (TPEs)

TPEs are soft and flexible. They are used for seals, gaskets, and comfort grips.

How Mold Makers Ensure High-Quality Single-Use Medical Products

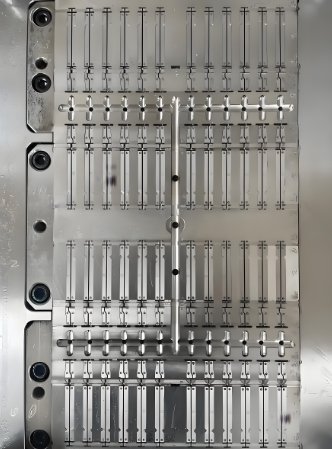

1. Precision in Mold Design

Mold makers create detailed molds for consistent results. This ensures each product meets strict medical standards.

2. Material Selection

Choosing the right plastic is crucial. Mold makers consider flexibility, durability, and sterility.

3. Cleanroom Manufacturing

Single-use medical products must be made in sterile environments. Cleanroom production prevents contamination.

4. High-Speed Production

Medical injection molding allows for mass production. This keeps costs low and ensures supply meets demand.

5. Quality Control and Testing

Molded parts go through rigorous testing. This ensures strength, flexibility, and chemical resistance.

Advantages of Medical Injection Molding for Single-Use Products

1. High Production Speed

Molding produces thousands of parts per hour.

2. Cost-Effective Manufacturing

Once the mold is created, production costs drop significantly.

3. Precision and Consistency

Injection molding ensures each product is identical and defect-free.

4. Sterility and Hygiene

Molded products meet strict medical hygiene standards.

5. Strong and Durable Materials

Plastics used in molding resist chemicals, impact, and temperature changes.

Challenges in Producing Single-Use Medical Products

1. Strict Regulatory Standards

Medical devices must meet FDA and ISO guidelines. Compliance is essential.

2. Balancing Cost and Quality

Materials must be affordable but still meet safety requirements.

3. Environmental Concerns

Single-use plastics create waste. New biodegradable options help reduce impact.

4. Maintaining Sterility

Products must remain contamination-free from production to use.

Innovations in Medical Injection Molding for Disposable Products

1. Biodegradable and Recyclable Plastics

New materials reduce environmental impact while maintaining safety.

2. Advanced Micro-Molding Techniques

Smaller, more precise parts improve medical device performance.

3. Smart Packaging for Sterility

New packaging solutions keep products sterile until use.

4. Automation in Manufacturing

Robotic systems improve efficiency and reduce errors.

The Future of Single-Use Medical Products in Injection Molding

1. More Sustainable Materials

Biodegradable plastics will become more common.

2. Enhanced Production Speed

Automation will further increase efficiency.

3. Greater Customization for Medical Needs

Injection molding will allow more specialized disposable devices.

4. Stricter Safety Standards

Improved regulations will ensure even safer medical products.

Medical injection molding plays a critical role in producing single-use medical products. These items improve patient safety and healthcare efficiency. Mold makers ensure high-quality molds for reliable, sterile, and cost-effective medical devices. As technology advances, injection molding will continue to shape the future of disposable medical products.