Speed matters.

Markets move fast.

You must move faster.

Electronic Injection Molding helps.

A skilled Mold Maker makes it even better.

Let’s see how to shorten product launch times.

Fast Design to Tooling

Use 3D Prototypes First

Quick 3D models test ideas fast.

No waiting for tooling.

Catch design errors early.

Electronic Injection Molding benefits from solid prep.

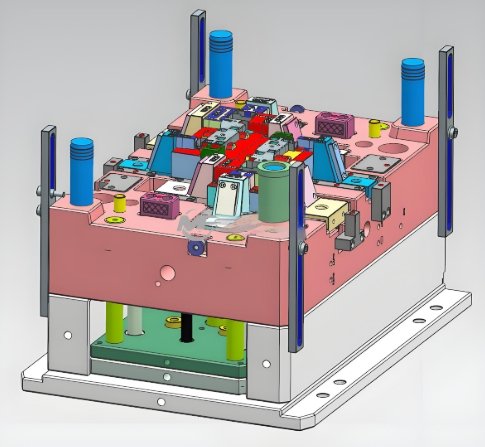

Digital Mold Design

Use CAD tools to save time.

No hand drawings.

Quick changes, easy reviews.

A smart Mold Maker uses software wisely.

Smart Material Choices

Faster Flow Resins

Some plastics fill molds faster.

They cool quickly.

They lower cycle time.

Electronic Injection Molding speeds up with them.

Pre-Colored Materials

Skip painting.

Use pre-colored plastic.

It’s clean and quick.

A good Mold Maker helps you choose right.

Rapid Tooling Techniques

Aluminum Molds

Aluminum molds are fast.

They’re good for low-volume runs.

They cost less too.

A skilled Mold Maker knows when to use them.

Modular Mold Bases

Reuse mold bases.

Just change inserts.

Faster than building from scratch.

Electronic Injection Molding becomes flexible and quick.

Process Optimization

Scientific Molding

Use data to set parameters.

No guessing.

Fewer trials.

A smart Mold Maker applies scientific molding.

Automation from the Start

Use robots early.

Don’t add them later.

That causes delays.

Automate handling, inspection, and trimming.

Shorter Cycle Times

Efficient Cooling

Cooling takes most of the time.

Use well-designed channels.

They cool faster and evenly.

Electronic Injection Molding becomes faster.

High-Speed Machines

Fast machines reduce shot time.

They maintain quality.

A professional Mold Maker matches mold to machine.

Quick Mold Changes

Standardized Components

Use common parts in molds.

It saves setup time.

Less custom work.

Electronic Injection Molding lines run smoother.

Quick-Change Systems

Use magnetic clamps or hydraulic locks.

Change molds in minutes.

Not hours.

A smart Mold Maker designs molds for quick change.

Rapid Testing and Approval

Short Runs First

Run a few parts first.

Check fit and function.

Fix issues early.

Fewer delays before production.

Automated Inspection

Use vision systems.

Check dimensions fast.

Reject faulty parts instantly.

A good Mold Maker can integrate sensors.

Collaborate Early with the Mold Maker

Design for Molding

Involve the Mold Maker from the start.

They spot design issues early.

Avoid rework later.

Electronic Injection Molding works best with teamwork.

Concurrent Engineering

Design the part and mold together.

It saves weeks.

And reduces risk.

Your Mold Maker becomes your best partner.

Pilot Production

Bridge Tooling

Use soft tooling first.

It gets products out fast.

Perfect for early sales.

A flexible Mold Maker offers this service.

Test in Real Conditions

Test parts in the real world.

Make final tweaks.

Then launch full production.

Electronic Injection Molding adapts quickly to changes.

Lean Production Setup

Just-in-Time Strategy

Don’t overproduce.

Make what you need.

Store less, waste less.

Speed up delivery.

Kanban Systems

Use cards or signals.

They pull materials just in time.

No delays in Electronic Injection Molding flow.

Flexible Manufacturing

Multi-Cavity Molds

Produce many parts at once.

Saves time per piece.

Faster total output.

A skilled Mold Maker balances quality and speed.

Family Molds

Make different parts in one mold.

All related to one product.

It speeds up assembly.

Less waiting for different parts.

Clear Communication

Track Every Step

Use software to monitor timelines.

Know where delays happen.

Fix them fast.

Electronic Injection Molding becomes more transparent.

Weekly Checkpoints

Hold reviews with your Mold Maker.

Share updates.

Solve issues early.

Stay on track to launch fast.

Stay Ready to Scale

Use Scalable Tools

Start small.

Ramp up fast.

Don’t rebuild everything.

Your Mold Maker should support scaling.

Plan for Growth

Design molds to expand.

Add cavities later.

Adapt without delays.

Electronic Injection Molding grows with you.

Speed wins in electronics.

Customers expect fast delivery.

To stay ahead, use smart molding.

Partner with a skilled Mold Maker.

Plan each step in advance.

Use fast tools, fast machines, and fast minds.

Electronic Injection Molding can shorten your lead time.

And get your product to market first.