Creating high-quality components for vehicles requires expertise and precision. Automotive Injection Molds are essential in the production process. Skilled Mold Makers craft these molds to perfection. This process combines art and technology. It is critical for producing high-end automotive parts.

The Role of Mold Makers

Expert Craftsmanship

A Mold Maker is like an artist. They use advanced tools and techniques. Their goal is to ensure the mold produces the perfect part.

Design Precision

The design phase is crucial. Mold Makers must consider every detail. Tolerances need to be exact. Any mistake could ruin the entire part.

Material Selection

Choosing the right material for the mold is critical. Mold Makers often use high-strength steel, aluminum, or alloys. These materials ensure durability and precision.

What Makes Automotive Injection Molds Special?

1. Durability

Automotive components must last for years. The molds are made to withstand high pressures and temperatures.

2. Complexity

Many automotive parts are intricate. Molds need to be designed for complex shapes and features.

3. Precision

Small imperfections can ruin a part. Automotive Injection Molds ensure every part fits perfectly.

4. Customization

Molds can be customized to meet specific needs. This is vital for producing unique vehicle designs.

5. Material Compatibility

Different automotive components require different materials. Molds must be able to handle these materials.

The Process of Creating Automotive Injection Molds

1. Initial Design

The first step is creating a design. The design must meet the specifications of the vehicle manufacturer. Mold Makers use CAD software to create accurate designs.

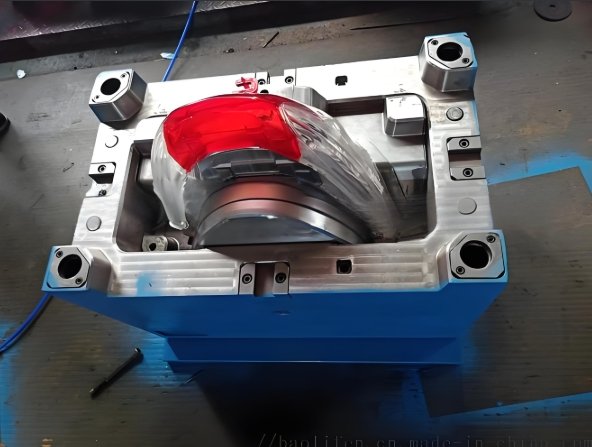

2. Prototype Creation

Once the design is complete, a prototype mold is created. This prototype helps test the design. It ensures the mold will work as intended.

3. Mold Production

After the prototype is tested and approved, the actual mold is produced. High-strength materials are used to create durable molds.

4. Testing and Refining

The mold is tested during production. This helps identify any potential issues. Any imperfections are corrected before mass production.

5. Mass Production

Once the mold is perfect, it enters mass production. Thousands of parts are created using the same mold.

Key Technologies in Automotive Injection Molds

1. Hot Runner Systems

Hot runners ensure that the molten plastic flows evenly into the mold. This minimizes waste and improves part quality.

2. Gas-Assisted Injection Molding

This technique uses gas to create hollow parts. It is ideal for lightweight automotive components.

3. Multi-Cavity Molds

These molds can create multiple parts at once. They increase efficiency and reduce production time.

4. Overmolding

Overmolding is a technique where one material is molded over another. This is used to create parts with multiple functions.

5. Smart Molds

Smart molds include sensors that monitor temperature and pressure. These sensors ensure that the process is optimal at all times.

Challenges in Automotive Injection Mold Manufacturing

1. Design Complexity

Automotive parts are becoming more complex. Mold Makers must design molds that can handle these complexities.

2. Material Constraints

Different materials have different properties. Mold Makers must choose the right material to ensure the mold functions as intended.

3. High Precision Requirements

Even small deviations in mold design can lead to defects. This requires extreme precision from Mold Makers.

4. Cost of Production

Creating molds is expensive. However, high-quality molds lead to high-quality parts, reducing costs in the long run.

5. Sustainability

The automotive industry is focused on sustainability. Mold Makers must create molds that reduce waste and use eco-friendly materials.

Why Automotive Injection Molds Are Essential

1. Efficiency

Injection molding allows for fast production. It is ideal for making large quantities of parts.

2. Quality

Automotive Injection Molds ensure that every part is made to exact specifications. This guarantees a high level of quality.

3. Cost-Effective

Although creating molds is costly, they save money in the long run by allowing mass production of parts.

4. Innovation

Injection molding allows for new innovations in automotive design. It enables the creation of unique and complex parts.

5. Sustainability

Using recyclable materials in the injection molding process helps reduce environmental impact.

The Future of Automotive Injection Molds

1. 3D Printing

3D printing technology is changing how molds are made. It allows for faster prototyping and more complex designs.

2. Lightweight Materials

There is a growing demand for lightweight materials. Automotive Injection Molds will need to adapt to handle these materials effectively.

3. Smart Technology

Smart molds will become more common. These molds will use sensors to monitor the production process in real time.

4. Sustainability

Sustainable practices will continue to be a focus. Mold Makers will use more eco-friendly materials and energy-efficient methods.

5. Global Collaboration

With the rise of global automotive manufacturers, collaboration between Mold Makers across different countries will increase.

The art of Automotive Injection Molds manufacturing requires expertise, precision, and innovation. Mold Makers play a crucial role in creating high-quality parts for the automotive industry. Advanced technologies and sustainable practices are shaping the future of injection molding. As vehicles become more complex, Mold Makers will continue to push the boundaries of design and manufacturing. Automotive Injection Molds are essential in creating the vehicles of tomorrow.