Medical technology is advancing rapidly. Medical injection molding plays a key role in producing high-quality devices. Mold makers develop precise and durable components for the healthcare industry. The demand for efficient, cost-effective solutions is increasing.

1. Why Demand for Medical Injection Molding Is Rising

1.1 Increased Need for Disposable Medical Products

- Hospitals require sterile, single-use items.

- Injection molding ensures mass production.

- Reduces infection risks in medical settings.

1.2 Growth of Minimally Invasive Surgery

- Advanced medical tools require precision-molded parts.

- Injection molding supports miniature, intricate designs.

- Mold makers create durable, high-performance components.

1.3 Expansion of Home Healthcare Devices

- Wearable monitors and drug delivery systems are rising.

- Patients need compact, lightweight devices.

- Injection molding produces customized, ergonomic designs.

2. Key Applications of Medical Injection Molding

2.1 Syringes and Drug Delivery Devices

- Mass-produced with strict quality control.

- Materials must be biocompatible and durable.

- Essential for safe medication administration.

2.2 Surgical Instruments

- Requires high precision and strength.

- Handles and casings use medical-grade plastics.

- Injection molding ensures consistent quality.

2.3 Medical Implants

- Custom molds create patient-specific components.

- Materials must be sterile and long-lasting.

- Used in orthopedic and dental applications.

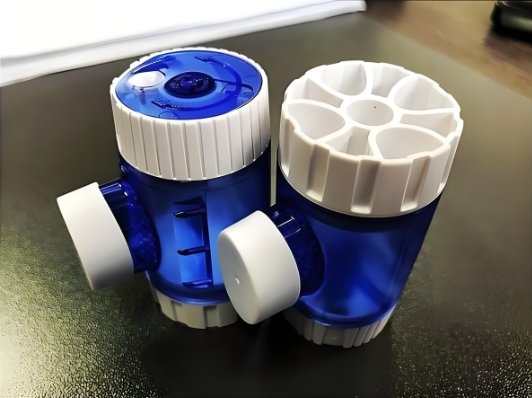

2.4 Diagnostic Equipment

- Enclosures and housings require precise molding.

- Protects sensitive electronic components.

- Ensures reliable performance in medical environments.

3. The Role of Mold Makers in Medical Manufacturing

3.1 Precision Tooling for High-Quality Parts

- Mold makers design complex, detailed molds.

- High-precision tooling ensures accuracy and consistency.

- Custom molds meet specific medical requirements.

3.2 Fast Production with Multi-Cavity Molds

- Allows high-volume production.

- Reduces cycle times and costs.

- Ensures efficient manufacturing.

3.3 Durable Materials for Long-Lasting Molds

- Medical tools require reliable mold designs.

- High-quality steel and aluminum improve mold lifespan.

- Reduces replacement and maintenance costs.

4. Advantages of Medical Injection Molding

4.1 High Precision and Consistency

- Ensures exact specifications for medical devices.

- Reduces product defects and waste.

- Meets strict regulatory standards.

4.2 Cost-Effective Mass Production

- Lower labor costs with automated production.

- High-speed molding reduces unit costs.

- Ideal for large-scale medical manufacturing.

4.3 Biocompatible and Sterile Materials

- Specialized plastics meet FDA and ISO standards.

- Withstand sterilization without degradation.

- Essential for implants and surgical devices.

5. Advanced Materials in Medical Injection Molding

5.1 High-Performance Polymers

- Polycarbonate and PEEK ensure strength and durability.

- Used in surgical and diagnostic devices.

- Provide resistance to heat and chemicals.

5.2 Silicone for Flexible Components

- Ideal for soft medical tubing and seals.

- Offers high elasticity and biocompatibility.

- Used in respiratory and IV components.

5.3 Antimicrobial Plastics for Infection Control

- Reduces bacterial growth on medical surfaces.

- Essential for hospital environments.

- Helps prevent cross-contamination.

6. The Impact of Automation in Medical Injection Molding

6.1 Robotics for Faster Production

- Reduces human error and labor costs.

- Improves repeatability and efficiency.

- Enables 24/7 production with minimal downtime.

6.2 AI-Powered Quality Control

- Detects defects and inconsistencies in real-time.

- Enhances precision and compliance.

- Reduces waste and material costs.

6.3 IoT Integration for Smart Monitoring

- Sensors track temperature, pressure, and cycle times.

- Provides real-time data for process optimization.

- Ensures consistent quality in high-volume production.

7. Challenges in Medical Injection Molding

7.1 Meeting Regulatory Requirements

- Devices must comply with FDA, ISO, and GMP standards.

- Strict testing ensures patient safety.

- Requires detailed documentation and traceability.

7.2 Material Selection for Specific Applications

- Biocompatibility is essential for implants and drug delivery.

- Certain materials require specialized processing techniques.

- Mold makers must optimize molds for unique material properties.

7.3 Rising Costs of High-Quality Manufacturing

- Medical-grade materials are expensive.

- Regulatory compliance increases production costs.

- Companies invest in automation to reduce expenses.

8. The Future of Medical Injection Molding

8.1 Growth in Personalized Medicine

- Demand for customized medical devices is increasing.

- 3D scanning allows patient-specific mold designs.

- Molding ensures scalability for mass production.

8.2 Sustainable Manufacturing Solutions

- Recyclable and biodegradable plastics reduce medical waste.

- Energy-efficient machines lower carbon footprint.

- Hospitals demand eco-friendly disposable products.

8.3 Advances in Micro Injection Molding

- Enables smaller, more precise medical components.

- Essential for nanotechnology and drug delivery systems.

- Requires highly specialized molding techniques.

The demand for medical injection molding is rising. Mold makers play a key role in producing high-quality, cost-effective medical devices. Advanced materials, automation, and sustainability drive the industry forward. As healthcare needs evolve, medical injection molding will continue to provide innovative solutions for the medical sector.