Electronic components require extreme precision. Electronic injection molding ensures accurate, high-quality parts. Tight tolerances play a critical role in maintaining product performance. Even the smallest deviation can lead to failure. Mold makers use advanced techniques to meet strict tolerance requirements.

This article explores the importance of tight tolerances, challenges, and best practices in electronic injection molding.

1. What Are Tight Tolerances?

1.1 Definition of Tight Tolerances

Tight tolerances refer to the small allowable deviations in part dimensions. In electronic injection molding, tolerances are often within microns.

1.2 Why Tight Tolerances Matter

- Ensure proper fit of electronic components

- Prevent signal loss and electrical failure

- Maintain structural integrity

- Improve overall product reliability

1.3 Typical Tolerances in Electronic Injection Molding

Most electronic parts require tolerances of ±0.05 mm or lower. Some micro-components need even tighter tolerances.

2. Challenges in Achieving Tight Tolerances

2.1 Material Selection

Different plastics shrink at different rates. High-performance materials like PBT, LCP, and PPS offer better dimensional stability.

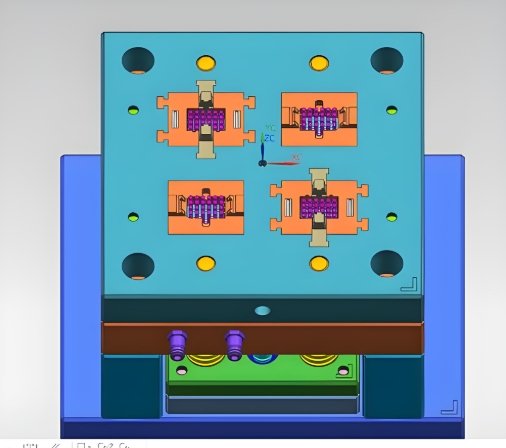

2.2 Mold Design and Precision

Mold makers must create highly accurate molds. Small design errors can cause defects.

2.3 Process Control

Temperature, pressure, and cooling rates affect final part dimensions. Any variation impacts tolerances.

2.4 Machine Accuracy

Older machines may struggle to maintain precision. Modern injection molding machines use servo-driven controls for better accuracy.

2.5 Environmental Factors

Humidity and temperature changes can cause material expansion or contraction. Proper storage and handling are necessary.

3. Role of Mold Makers in Achieving Tight Tolerances

3.1 High-Precision Mold Manufacturing

Mold makers use CNC machining, EDM, and laser cutting to create ultra-precise molds.

3.2 Mold Cavity Inspection

Before production, molds undergo strict dimensional checks to ensure accuracy.

3.3 Use of High-Quality Steel

Premium steel grades reduce wear and maintain tight tolerances over long production runs.

3.4 Optimized Cooling Systems

Uniform cooling prevents warping and shrinkage, ensuring parts remain within tolerance.

4. Best Practices for Maintaining Tight Tolerances

4.1 Advanced Injection Molding Machines

Modern machines with closed-loop control systems adjust parameters in real time.

4.2 In-Process Quality Control

Real-time monitoring detects variations early, reducing waste and improving efficiency.

4.3 Post-Molding Inspection

Coordinate measuring machines (CMM) and optical sensors verify final part dimensions.

4.4 Automation for Consistency

Robotic handling minimizes human error, improving repeatability in high-volume production.

5. Applications Requiring Tight Tolerances

5.1 PCB Connectors

Small deviations can cause poor electrical connections and signal loss.

5.2 Micro-Switches

Precision ensures proper actuation and reliable performance.

5.3 LED Components

Uniform part dimensions improve light output and thermal management.

5.4 Smartphone Housings

Accurate molding ensures perfect fit for internal components.

5.5 Automotive Sensors

Sensors must meet strict tolerances to function correctly in harsh environments.

6. Future of Tight Tolerances in Electronic Injection Molding

6.1 AI-Driven Process Control

Artificial intelligence optimizes machine settings for maximum precision.

6.2 Nanotechnology in Mold Making

New materials and coatings reduce tool wear, improving mold longevity.

6.3 3D Printing for Prototype Validation

Rapid prototyping helps mold makers refine designs before full production.

6.4 Sustainable Manufacturing

Improved molding techniques reduce waste while maintaining tight tolerances.

Tight tolerances are essential for electronic injection molding. They ensure product reliability, performance, and longevity. Mold makers use advanced technology to maintain precision in every part. By optimizing materials, processes, and quality control, manufacturers can achieve high accuracy in electronic components.

As technology evolves, precision requirements will become even stricter. Investing in high-precision mold making and automation will be key to staying competitive in electronic injection molding.