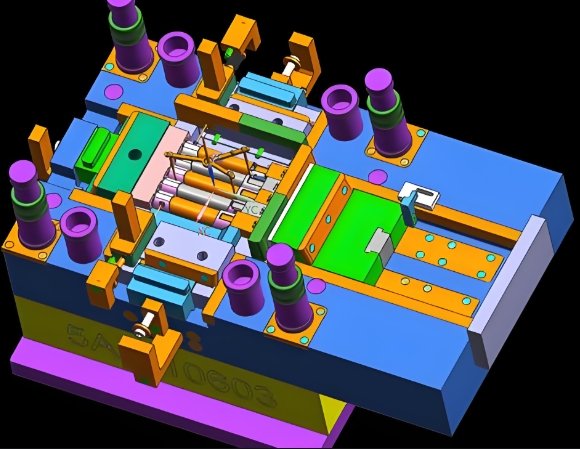

Technology is transforming mold production. Automotive injection molds are now more precise and efficient. A skilled mold maker uses advanced tools to enhance quality.

The Role of Technology in Mold Making

1. Precision Engineering

Accuracy is crucial. Automotive injection molds require tight tolerances. A mold maker uses high-tech machines to ensure precision.

2. Faster Production

Modern machines speed up processes. Automotive injection molds are made faster with automation. A mold maker reduces lead times.

3. Improved Material Usage

Technology optimizes material selection. Automotive injection molds use advanced plastics. A mold maker minimizes waste.

Advanced Manufacturing Techniques

1. CNC Machining

CNC machines shape metal accurately. Automotive injection molds need precision cutting. A mold maker programs CNC tools for exact dimensions.

2. EDM (Electrical Discharge Machining)

EDM carves intricate details. Automotive injection molds need complex shapes. A mold maker uses EDM for fine features.

3. 3D Printing for Prototypes

3D printing speeds up testing. Automotive injection molds require prototypes. A mold maker creates test models quickly.

4. High-Precision Laser Cutting

Lasers cut with extreme accuracy. Automotive injection molds use laser tech for fine edges. A mold maker ensures smooth finishes.

Smart Automation in Mold Making

1. Robotic Machining

Robots improve consistency. Automotive injection molds are made with robotic precision. A mold maker ensures uniform quality.

2. Automated Inspection Systems

Machines check dimensions automatically. Automotive injection molds require strict accuracy. A mold maker uses AI-powered inspection.

3. AI and Machine Learning

AI predicts defects. Automotive injection molds benefit from smart adjustments. A mold maker prevents errors before they happen.

4. Digital Twin Technology

A digital twin simulates molds. Automotive injection molds are tested virtually. A mold maker perfects designs before production.

Material Innovations for Automotive Molds

1. High-Performance Polymers

New plastics enhance strength. Automotive injection molds use heat-resistant polymers. A mold maker selects top materials.

2. Composite Materials

Stronger blends improve durability. Automotive injection molds use reinforced plastics. A mold maker enhances part performance.

3. Eco-Friendly Bioplastics

Green materials reduce waste. Automotive injection molds embrace sustainability. A mold maker focuses on recyclable options.

4. Metal Injection Molding (MIM)

MIM enhances strength. Automotive injection molds use fine metal powders. A mold maker creates ultra-durable parts.

Quality Control with Technology

1. Optical Scanning

Lasers check for defects. Automotive injection molds need flaw detection. A mold maker ensures perfect parts.

2. Real-Time Monitoring

Sensors track production. Automotive injection molds improve with live data. A mold maker makes quick adjustments.

3. Digital Inspection Reports

Reports ensure consistency. Automotive injection molds are checked digitally. A mold maker verifies every measurement.

4. Thermal Imaging for Mold Cooling

Heat maps detect issues. Automotive injection molds need even cooling. A mold maker prevents defects from heat imbalance.

The Impact of Smart Factories on Mold Making

1. IoT Integration

Machines connect to networks. Automotive injection molds benefit from smart data. A mold maker tracks every step remotely.

2. Predictive Maintenance

AI prevents breakdowns. Automotive injection molds last longer with predictive care. A mold maker reduces downtime.

3. Energy-Efficient Manufacturing

Tech lowers power use. Automotive injection molds are made sustainably. A mold maker reduces carbon footprints.

4. Blockchain for Supply Chain Management

Secure tracking prevents errors. Automotive injection molds follow a digital record. A mold maker ensures traceability.

Future Trends in Automotive Mold Making

1. Nano-Enhanced Molding

Nanotech improves material strength. Automotive injection molds will use nano-coatings. A mold maker ensures better durability.

2. AI-Driven Design Optimization

AI creates better molds. Automotive injection molds will be smarter. A mold maker benefits from machine learning.

3. Augmented Reality (AR) for Training

AR enhances learning. Automotive injection molds require skilled handling. A mold maker trains faster with AR tools.

4. Fully Autonomous Factories

Machines will run everything. Automotive injection molds will be made without human errors. A mold maker supervises AI-driven production.

Technology improves mold making. Automotive injection molds are more precise and efficient. A skilled mold maker ensures high-quality, advanced manufacturing. The future promises even smarter solutions.