Conductive polymers are transforming electronic injection molding. They combine electrical conductivity with the flexibility of plastics. This makes them ideal for electronic components. Mold makers use these materials to improve circuit performance, reduce weight, and enhance durability.

This article explores conductive polymers, their benefits, applications, and challenges in electronic manufacturing.

1. What Are Conductive Polymers?

Conductive polymers are plastics that conduct electricity. Unlike metals, they are lightweight, corrosion-resistant, and easy to mold.

1.1 How Conductive Polymers Work

- They contain intrinsically conductive molecules.

- They can be doped with additives to improve conductivity.

- Some polymers have metallic or carbon-based fillers.

1.2 Types of Conductive Polymers

- Intrinsically Conductive Polymers (ICPs) – Polyaniline, Polypyrrole, PEDOT.

- Filled Conductive Polymers – Plastics mixed with carbon, silver, or copper.

- Hybrid Conductive Polymers – Combine conductive fillers with standard plastics.

2. Benefits of Conductive Polymers in Electronic Injection Molding

2.1 Lightweight and Flexible

- Reduces weight in portable electronics.

- Allows flexible circuit applications.

2.2 Corrosion-Resistant

- Outperforms metals in harsh environments.

- Extends product lifespan.

2.3 Cost-Effective

- Cheaper than traditional metal components.

- Easier and faster to mold.

2.4 Customizable Conductivity

- Adjust conductivity levels with different fillers.

- Ensures optimal performance for specific applications.

2.5 EMI Shielding

- Protects devices from electromagnetic interference.

- Improves signal integrity in electronic circuits.

3. Applications of Conductive Polymers in Electronics

3.1 Printed Circuit Boards (PCBs)

- Used as flexible PCB substrates.

- Reduces manufacturing complexity.

3.2 Connectors and Switches

- Enables low-resistance electrical contacts.

- Enhances wear resistance.

3.3 Sensors and Wearables

- Used in biosensors and flexible electronics.

- Improves user comfort and durability.

3.4 Antistatic Packaging

- Prevents static charge buildup in sensitive components.

- Ensures safe storage and transport.

3.5 Smart Textiles

- Enables conductive fabrics for wearable electronics.

- Improves integration of sensors into clothing.

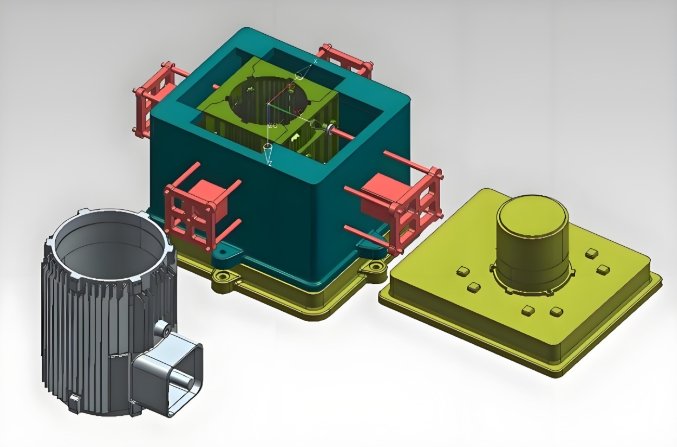

4. Role of a Mold Maker in Conductive Polymer Molding

4.1 Tooling Design

- Creates precise molds for conductive polymer parts.

- Ensures tight tolerances for electronic applications.

4.2 Material Selection

- Chooses appropriate conductive fillers for performance.

- Balances conductivity and mechanical strength.

4.3 Process Optimization

- Controls temperature and pressure for defect-free molding.

- Uses advanced injection techniques for uniform material flow.

5. Challenges in Conductive Polymer Injection Molding

5.1 Filler Distribution

- Conductive fillers must be evenly dispersed.

- Poor mixing leads to inconsistent conductivity.

5.2 High Processing Temperatures

- Some polymers degrade at high temperatures.

- Precise temperature control is critical.

5.3 Surface Resistivity Control

- Small changes in formulation affect conductivity.

- Requires strict quality testing.

5.4 Adhesion Issues

- Conductive polymers may not bond well with other materials.

- Proper surface treatment is necessary.

6. Advanced Techniques for Conductive Polymer Molding

6.1 Multi-Shot Injection Molding

- Combines non-conductive and conductive layers in one process.

- Improves circuit integration in electronic components.

6.2 Insert Molding

- Embeds metal connectors inside conductive polymer parts.

- Enhances electrical contact reliability.

6.3 Overmolding

- Adds protective layers over conductive components.

- Improves durability and insulation.

6.4 Micro-Injection Molding

- Produces miniature conductive components.

- Supports compact electronic designs.

7. Future Trends in Conductive Polymer Molding

7.1 3D Printing with Conductive Polymers

- Enables rapid prototyping of electronic parts.

- Reduces waste and material costs.

7.2 Smart Polymers for IoT Devices

- Creates self-healing and adaptive materials.

- Enhances flexible and wearable electronics.

7.3 Sustainable Conductive Polymers

- Develops biodegradable conductive materials.

- Reduces electronic waste.

7.4 AI-Driven Process Optimization

- Uses machine learning to improve molding efficiency.

- Ensures higher precision and lower defects.

Conductive polymers are reshaping electronic injection molding. They offer lightweight, flexible, and cost-effective solutions for modern electronics. Mold makers play a key role in optimizing material selection, tooling, and processing techniques.

As technology advances, conductive polymers will continue to improve electronic manufacturing. Innovations in 3D printing, smart materials, and AI will further enhance their capabilities. By overcoming challenges and adopting new technologies, manufacturers can achieve high-quality conductive polymer components for next-generation electronic devices.