Aerospace electronics need extreme precision. Every component must withstand heat, pressure, and vibration. Electronic injection molding ensures high-performance parts. Mold makers create lightweight, durable components for aircraft systems. From sensors to control panels, injection molding shapes aerospace technology.

1. Why Aerospace Electronics Need Injection Molding

1.1 High Precision for Critical Components

Aircraft systems require exact measurements. Injection molding ensures uniformity.

1.2 Lightweight Materials for Fuel Efficiency

Aerospace parts must be light but strong. Molded plastics reduce weight.

1.3 Heat and Chemical Resistance

Aircraft electronics endure extreme temperatures. Molded parts resist heat and chemicals.

1.4 Vibration and Shock Absorption

Injection-molded materials absorb shocks. This protects sensitive electronics.

1.5 Cost-Effective Mass Production

Injection molding produces high volumes quickly. This reduces manufacturing costs.

2. Aerospace Electronics That Use Injection Molding

2.1 Flight Control Systems

- Control panels and buttons.

- Sensor housings for stability control.

2.2 Communication Systems

- Antenna casings.

- Insulated connectors.

2.3 Power Distribution Units

- Circuit board enclosures.

- High-voltage insulators.

2.4 Avionics and Navigation Equipment

- Radar and GPS housings.

- Wire harness connectors.

2.5 In-Flight Entertainment Systems

- Lightweight casings for screens.

- Noise-resistant speaker components.

3. Key Materials for Aerospace Electronic Injection Molding

3.1 Polyetheretherketone (PEEK)

- High heat resistance.

- Excellent mechanical strength.

3.2 Polyphenylene Sulfide (PPS)

- Withstands extreme temperatures.

- Chemical and flame-resistant.

3.3 Liquid Crystal Polymer (LCP)

- Perfect for miniaturized electronics.

- Superior electrical insulation.

3.4 Polyimide (PI)

- Extremely heat-resistant.

- Used in high-temperature circuits.

3.5 Acrylonitrile Butadiene Styrene (ABS)

- Impact-resistant.

- Used in lightweight enclosures.

4. The Injection Molding Process for Aerospace Electronics

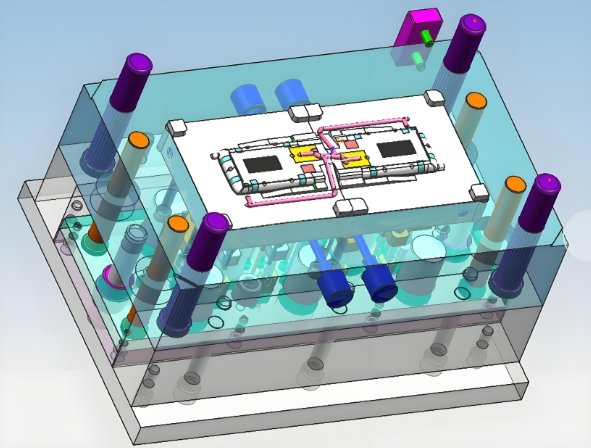

4.1 Step 1: Designing the Mold

Mold makers create detailed molds for each component.

4.2 Step 2: Material Selection

Engineers choose heat-resistant plastics.

4.3 Step 3: Injection Molding Process

Molten plastic is injected into precision molds.

4.4 Step 4: Cooling and Solidification

Parts cool quickly for a stable structure.

4.5 Step 5: Quality Testing

Every component undergoes strict testing.

4.6 Step 6: Assembly and Integration

Molded parts are assembled into aerospace systems.

5. Challenges in Aerospace Electronic Injection Molding

5.1 Meeting Aerospace Industry Standards

Parts must pass FAA and ESA regulations.

5.2 Extreme Durability Requirements

Components must last under high stress.

5.3 Lightweight but Strong Materials

Balancing strength and weight is crucial.

5.4 Resistance to High Altitude Conditions

Materials must function in low-pressure environments.

5.5 Electrical Conductivity and Insulation

Proper insulation prevents electronic failures.

6. Innovations in Aerospace Electronic Injection Molding

6.1 Overmolding for Enhanced Durability

Combining materials strengthens aerospace parts.

6.2 Multi-Shot Molding for Complex Components

Allows different materials in a single part.

6.3 Smart Polymers for Adaptive Electronics

Self-healing plastics enhance durability.

6.4 3D Printing for Rapid Prototyping

Speeds up new product development.

6.5 AI-Driven Quality Control

Artificial intelligence ensures precision in production.

7. The Future of Injection Molding in Aerospace Electronics

7.1 More Advanced Lightweight Materials

Future polymers will be even stronger and lighter.

7.2 AI and Automation for Faster Production

AI-driven molding increases efficiency.

7.3 Higher Precision in Micro-Molding

Tiny components will be even more accurate.

7.4 Sustainable and Eco-Friendly Aerospace Plastics

Recyclable materials will reduce waste.

7.5 Improved Heat and Radiation Resistance

New materials will withstand extreme conditions.

Electronic injection molding plays a vital role in aerospace electronics. Mold makers ensure precision, strength, and lightweight components. As technology advances, injection molding will continue to shape the future of aerospace engineering.