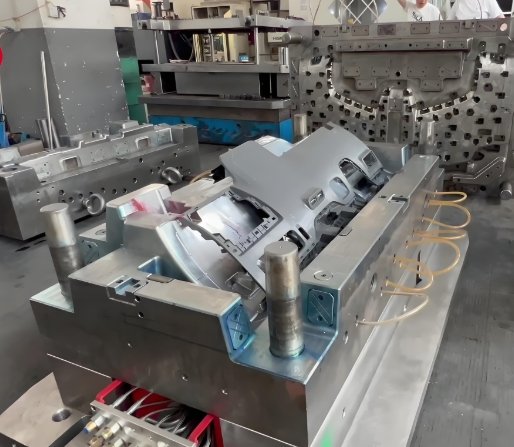

The automotive industry relies heavily on Automotive Injection Molds. Expert Mold Makers create molds that improve vehicle components. New trends are shaping how molds are designed and produced. These innovations boost efficiency, reduce costs, and improve quality.

The Importance of Automotive Injection Molds

Automotive Injection Molds are essential for making vehicle parts. They allow mass production with consistency. A skilled Mold Maker ensures the molds meet strict industry standards. Modern designs support complex parts with precision.

Emerging Trends in Mold Design

1. Lightweight Mold Materials

Lightweight materials reduce mold weight. Aluminum and composite materials are gaining popularity. These materials improve handling and speed up production.

2. 3D Printing for Prototyping

3D printing accelerates prototyping. It allows quick testing of mold designs. This reduces development time.

3. Eco-Friendly Practices

Sustainability is now a focus. Recyclable plastics and energy-efficient machines are used. Mold designs aim to minimize material waste.

4. AI and Automation

AI optimizes mold designs. Automated systems improve precision. These technologies reduce errors and speed up production.

Role of Mold Makers in Trend Adoption

1. Innovative Thinking

Mold Makers adopt new technologies to stay competitive. They embrace trends like AI and automation.

2. Collaboration

They work closely with engineers. This ensures molds meet specific needs.

3. Continuous Learning

Skilled Mold Makers stay updated on the latest materials and techniques.

Benefits of Following Trends

1. Improved Efficiency

Modern molds reduce production time. Faster cycles mean more parts in less time.

2. Enhanced Quality

Advanced molds create precise and durable parts.

3. Cost Savings

Trendy designs lower material waste and energy costs.

Innovations in Automotive Injection Molds

1. Cooling Systems

New cooling systems improve mold performance. They reduce cooling times. This speeds up production.

2. Multi-Cavity Molds

These molds produce multiple parts at once. They are ideal for mass production.

3. Smart Sensors

Sensors in molds monitor temperature and pressure. This ensures optimal performance.

Trends in Part Applications

1. Lightweight Parts for EVs

Electric vehicles (EVs) need lightweight parts. Modern molds help produce these efficiently.

2. Custom Interiors

Luxury vehicles require unique interior designs. Custom molds deliver high-quality finishes.

3. Functional Engine Components

Molds now focus on producing durable engine covers and holders.

Challenges in Trend Adoption

1. High Costs

New technologies can be expensive. Companies need to weigh the benefits.

2. Learning Curve

Adopting trends requires training. Mold Makers must learn new techniques.

3. Material Compatibility

Not all materials suit every mold design. Careful selection is crucial.

Future of Automotive Injection Molds

1. Personalized Designs

Custom molds will enable personalized vehicle components.

2. Sustainability Focus

Green practices will dominate mold designs.

3. AI Integration

AI will play a larger role in optimizing designs.

Why Partner with an Expert Mold Maker?

1. Precision Work

Experienced Mold Makers deliver accurate molds.

2. Innovative Solutions

They adopt the latest trends to meet your needs.

3. Reliable Support

Good Mold Makers offer maintenance and updates.

The trends in Automotive Injection Molds are revolutionizing manufacturing. Skilled Mold Makers are key to adopting these changes. They ensure molds are precise, durable, and efficient. Staying updated with trends boosts production and saves costs.

Choose a reliable Mold Maker to keep up with innovation. Their expertise ensures your molds meet modern demands.