Medical devices require precision. Medical injection molding ensures accuracy. A skilled mold maker delivers high-quality parts. This process is vital for healthcare advancements.

1. What is Medical Injection Molding?

Definition

Medical injection molding creates plastic medical components. It ensures consistency and precision.

How It Works

Molten plastic is injected into a mold. The shape hardens into a precise medical part.

Importance in Healthcare

Medical products need strict standards. This process guarantees safety and accuracy.

2. Benefits of Medical Injection Molding

High Precision Production

Even the smallest details are accurate. Perfect for surgical tools and implants.

Cost-Effective Manufacturing

Mass production reduces costs. More products, less waste.

Biocompatibility

Materials used are safe for human contact. Ensures no harmful reactions.

Scalability

Production can be small or large. Adaptable to demand.

Fast Production Cycles

Automation speeds up manufacturing. Critical for urgent medical needs.

3. Role of a Mold Maker in Medical Injection Molding

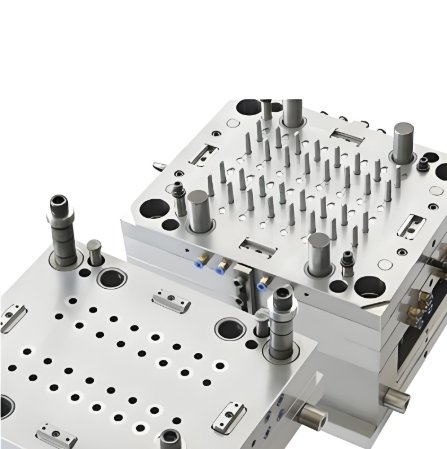

Custom Mold Design

A mold maker creates precise molds. Designs fit medical specifications.

Material Selection Expertise

Choosing the right plastic is crucial. Biocompatible and durable materials are required.

Ensuring Tight Tolerances

Molds must be exact. Even minor defects can cause failure.

Long Mold Lifespan

A high-quality mold lasts for many cycles. Ensures consistent production.

4. Common Medical Products Made with Injection Molding

Surgical Instruments

Scalpels, forceps, and retractors need high precision.

Implantable Devices

Pacemakers, joint replacements, and stents use biocompatible plastics.

Diagnostic Equipment

Test tubes, sample containers, and lab trays require strict accuracy.

Drug Delivery Systems

Syringes, inhalers, and insulin pens must be defect-free.

IV Components

Valves, tubing, and connectors are mass-produced efficiently.

5. Materials Used in Medical Injection Molding

Thermoplastics

- Polycarbonate (PC) – Strong and impact-resistant.

- Polypropylene (PP) – Lightweight and chemical-resistant.

- Polyetheretherketone (PEEK) – High heat resistance.

Silicone Rubber

Flexible and biocompatible. Used in medical tubing.

Bio-Resorbable Polymers

Dissolve in the body over time. Used for sutures and implants.

6. Cleanroom Injection Molding

Why Cleanrooms Matter

Medical parts must be sterile. Contaminants can cause infections.

Types of Cleanroom Molding

- ISO Class 7 (10,000 particles per cubic foot)

- ISO Class 8 (100,000 particles per cubic foot)

Strict Hygiene Protocols

Workers wear protective gear. Machines are sterilized regularly.

7. Quality Control in Medical Injection Molding

Inspection Techniques

- Visual Inspections – Detects surface defects.

- Automated Scanning – Ensures precision.

- Dimensional Testing – Confirms exact measurements.

Compliance with Regulations

- FDA Approval – Ensures product safety.

- ISO 13485 Certification – Guarantees quality standards.

- Good Manufacturing Practices (GMP) – Maintains consistency.

8. Advanced Injection Molding Techniques for Healthcare

Micro-Molding

Used for tiny medical parts. Critical for minimally invasive surgery.

Overmolding

Combines materials for better functionality. Common in medical grips.

Insert Molding

Encapsulates metal components in plastic. Used for surgical handles.

9. Choosing the Right Medical Mold Maker

Experience in Medical Molding

A reliable mold maker has years of expertise. Specialization ensures quality.

Technology and Equipment

Modern facilities use automated systems. Increases accuracy and speed.

Prototyping Capabilities

Testing before production reduces risks. Ensures perfect designs.

Regulatory Compliance

Certified manufacturers follow strict guidelines. Guarantees patient safety.

10. Medical Injection Molding for Emergency Situations

Rapid Production of Medical Supplies

Pandemics require fast manufacturing. Injection molding meets demand.

Scalability for High Demand

Large-scale production ensures supply. Crucial for emergency response.

Cost-Effective Mass Production

More products at lower costs. Helps reduce healthcare expenses.

11. Innovations in Medical Injection Molding

3D Printing for Prototyping

Speeds up mold development. Reduces trial-and-error.

AI-Powered Quality Control

Automated systems detect defects. Ensures zero errors.

Sustainable Medical Plastics

Eco-friendly materials reduce waste. Biodegradable options available.

12. Reducing Errors in Medical Injection Molding

Strict Quality Checks

Every part undergoes inspection. Ensures accuracy.

Advanced Sensor Technology

Detects molding defects instantly. Reduces product failures.

Regular Mold Maintenance

A well-maintained mold lasts longer. Prevents manufacturing issues.

13. Future Trends in Medical Injection Molding

Smart Medical Devices

Wearable tech requires precision molding. Increases patient monitoring efficiency.

Biodegradable Implants

Dissolvable medical plastics improve treatment. Eliminates secondary surgeries.

Nano-Molding for Microscopic Devices

Tiny devices improve drug delivery. Revolutionizing medical treatments.

14. Selecting the Best Injection Molding Partner

Check Certifications

ISO 13485 and FDA approval ensure quality.

Review Case Studies

Successful projects prove reliability.

Assess Production Capabilities

High-volume production ensures scalability.

Ensure Strong Communication

A good partner offers full transparency.

Medical injection molding is essential for healthcare. A skilled mold maker ensures high precision, safety, and cost-efficiency. Choosing the right manufacturer guarantees top-quality medical products.