Choosing the right Injection Mould Company is crucial for businesses that rely on high-quality molded parts. The automotive, consumer goods, and electronics industries all depend on the precision and durability of molded products. But what makes a good Injection Mould Company stand out? This article will highlight the essential qualities that a reliable Injection Mould Company must have, including expertise in Injection Molding, skilled Mold Makers, and top-quality Injection Molds.

Expertise in Injection Molding

The first and most important quality of a good Injection Mould Company is deep expertise in the Injection Molding process. Injection Molding is a complex technique that requires specialized knowledge to ensure high precision and efficiency. A good company will have a team with years of experience in Injection Molding. They will understand the nuances of the process, from selecting the right materials to controlling temperature and pressure during molding.

In addition, a skilled Injection Mould Company can handle different types of Injection Molding, including thermoplastic, thermosetting, and metal injection molding. The company should be familiar with a variety of materials to suit different applications. Whether it’s for consumer products or industrial parts, expertise in Injection Molding is a non-negotiable factor in ensuring that the final product meets all quality standards.

Skilled Mold Makers

Another key factor is having skilled Mold Makers. Mold Makers are experts in designing and creating the molds that will shape the final product. They are responsible for turning concepts into physical molds that can withstand high pressures and temperatures during the Injection Molding process. Good Mold Makers understand the importance of accuracy and detail. They can produce molds that will deliver perfectly molded products every time.

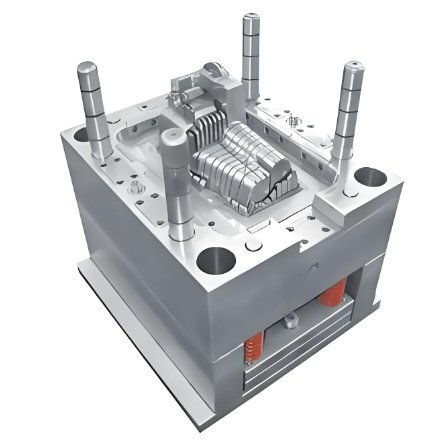

A good Injection Mould Company will have Mold Makers who use the latest technology and software to design molds. They will create molds that are not only precise but also durable. High-quality molds are essential for producing consistent results over time. If the mold is not made correctly, the product will not meet specifications, and production delays can occur. Experienced Mold Makers ensure the mold design is efficient, cost-effective, and suited for mass production.

High-Quality Injection Molds

Quality Injection Molds are at the heart of the Injection Molding process. A reputable Injection Mould Company will use top-notch materials to create molds that can handle the stresses of high-volume production. Injection Molds must be made from durable materials, such as high-grade steel or aluminum, to ensure that they perform well over time. These molds are expensive, so using the best materials is crucial for ensuring a long service life.

Good Injection Mould Companies also have a rigorous testing process for their molds. Before any mold is used in production, it should be tested to make sure it meets the required standards. The mold should be checked for accuracy, durability, and efficiency. If a mold is not up to par, it can lead to defects in the final product, resulting in delays and extra costs.

Advanced Technology and Equipment

A good Injection Mould Company must invest in advanced technology and state-of-the-art equipment. This includes high-precision machines for Injection Molding, 3D printing technology for prototype testing, and automated systems for mold making and quality checks. These technologies allow the company to offer faster turnaround times and ensure that every part meets the required specifications.

Advanced equipment also enables a company to handle more complex projects. Whether you’re looking for small, intricate parts or large, durable components, the right equipment will ensure the project is completed on time and to high standards. A modern Injection Mould Company will be well-equipped to meet your specific needs, providing both quality and efficiency.

Quick Turnaround Time

A reliable Injection Mould Company should be able to offer fast and efficient service. Delays in production can cost businesses valuable time and money. That’s why it’s important to choose a company that can provide quick turnaround times without sacrificing quality.

Fast turnaround times are often made possible by efficient project management and an organized workflow. The company should have the capacity to manage large orders and handle tight deadlines. A good Injection Mould Company should also be able to scale production as needed, depending on demand. This is especially important for industries like automotive or electronics, where time-sensitive production is crucial.

Cost-Effective Solutions

Cost is always an important factor in choosing an Injection Mould Company. However, choosing the cheapest option is not always the best. Instead, businesses should look for a company that offers cost-effective solutions while maintaining high quality. A good Injection Mould Company will offer competitive pricing and work with clients to reduce costs without compromising on the final product’s quality.

One way a company can offer cost-effective solutions is through material optimization. Injection Molding often involves selecting the right materials for the project, and a good Injection Mould Company can advise clients on the best options to reduce waste and save money.

Excellent Customer Service

Customer service is another important quality of a good Injection Mould Company. The company should be responsive to inquiries and work closely with clients throughout the entire process. This includes providing regular updates, answering any questions, and offering guidance on material selection, mold design, and production timelines. Communication is key to ensuring that expectations are met and the final product is delivered on time.

Moreover, a reputable Injection Mould Company will be transparent about their processes and costs. They will work with clients to solve any challenges that arise during production and will ensure that the final product meets all quality standards.

Innovation and Continuous Improvement

The best Injection Mould Companies are always striving for improvement and innovation. They stay up-to-date with the latest trends, technologies, and techniques in the Injection Molding industry. This means they are constantly finding new ways to improve their processes, increase efficiency, and deliver better results to their clients.

Whether it’s investing in new machinery or experimenting with new materials, a good Injection Mould Company will always be looking for ways to improve. This commitment to innovation ensures that they can continue to meet the changing demands of their clients and stay competitive in the industry.

In conclusion, a good Injection Mould Company must have a combination of expertise, experience, and modern equipment. Key qualities such as skilled Mold Makers, high-quality Injection Molds, and a deep understanding of Injection Molding processes are essential. A reliable company will also offer quick turnaround times, cost-effective solutions, excellent customer service, and a commitment to innovation. When looking for an Injection Mould Company, always consider these qualities to ensure the best possible outcome for your manufacturing needs.