Glue stains on injection molds are a common issue. They can affect the quality of the final product. Mold makers must understand why these stains occur. Knowing the causes helps in preventing them.

What Are Glue Stains?

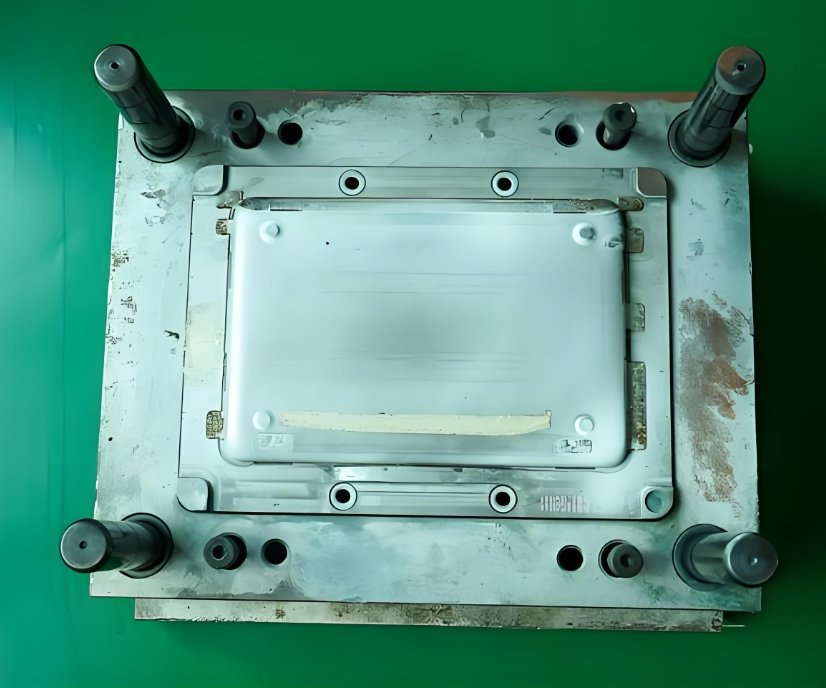

Glue stains appear as unwanted marks on the mold surface. They result from the adhesive used during the injection molding process. When the adhesive is not properly controlled, it can leave residues. These residues can stick to the mold, causing defects in the final product.

Common Causes of Glue Stains

- Excessive Adhesive UseOne major cause of glue stains is excessive adhesive application. If too much adhesive is used, it can overflow. This overflow creates glue stains on the mold surface. Mold makers must ensure the correct amount is applied.

- Improper CuringAdhesives need time to cure properly. If the curing process is not followed, glue stains can occur. Inadequate curing leaves residues that can stick to the mold. Mold makers should monitor the curing time carefully.

- Material Compatibility IssuesSometimes, the adhesive is not compatible with the mold material. This incompatibility can lead to residue buildup. Mold makers should choose adhesives that work well with their specific materials. Compatibility helps reduce the risk of glue stains.

- Temperature FluctuationsTemperature plays a crucial role in the adhesive process. High or low temperatures can affect how the adhesive behaves. If the temperature is too high, the adhesive may not set properly. This can result in glue stains on the mold surface.

- Contaminated SurfacesContaminants on the mold surface can lead to glue stains. Dust, oil, or dirt can interfere with adhesive bonding. Mold makers must ensure that the mold surface is clean before applying adhesive. A clean surface reduces the risk of stains.

- Incorrect Application TechniqueThe technique used to apply the adhesive matters. If the application is uneven, some areas may get too much glue. This unevenness can lead to stains. Mold makers should train staff on proper adhesive application techniques.

- Inadequate Cleaning ProceduresAfter each use, molds should be cleaned thoroughly. Inadequate cleaning can leave residual glue. This leftover adhesive can create stains in future uses. Mold makers must establish effective cleaning protocols.

Preventing Glue Stains

- Control Adhesive Application:Mold makers should control the amount of adhesive used. This control prevents overflow and excess glue. Using precise application tools can help achieve accuracy.

- Monitor Curing Conditions:Proper curing conditions are vital. Mold makers should monitor temperature and humidity. Ensuring the right environment helps the adhesive cure correctly.

- Select Compatible Adhesives :Choosing the right adhesive is essential. Mold makers must research adhesives for compatibility. Using suitable adhesives reduces the risk of stains.

- Maintain Clean Surfaces:Regular cleaning is crucial for mold maintenance. Mold makers should clean surfaces before applying adhesive. A clean mold surface helps prevent glue stains.

- Train Staff on Application TechniquesStaff should receive training on proper adhesive application. This training ensures that they use the correct techniques. Proper application reduces the risk of excess glue and stains.

- Implement Regular Inspections:Regular inspections of molds can catch issues early. Mold makers should check for any glue buildup. Addressing these problems promptly helps maintain mold quality.

- Use Quality Cleaning Agents:Using the right cleaning agents can help remove residues. Mold makers should choose cleaners that effectively dissolve adhesives. Quality cleaning agents ensure molds remain in top condition.

In conclusion, glue stains on injection molds can cause significant issues. Understanding the causes helps mold makers prevent these stains. By controlling adhesive use, monitoring curing, and maintaining clean surfaces, they can minimize the risk. Proper training and regular inspections are also crucial. With these strategies, injection mould companies can ensure high-quality production and reduce defects in molded parts.