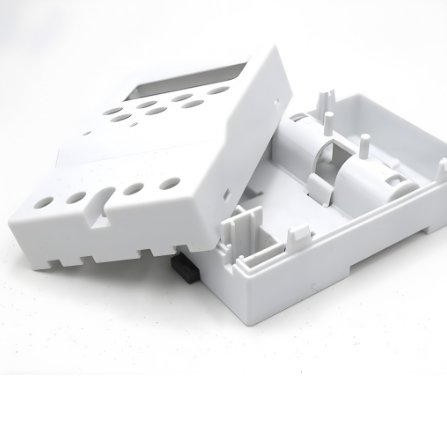

The Best Tooling Materials for Electronic Injection Molding

Choosing the right tooling material is critical in Electronic Injection Molding. A skilled Mold Maker understands this well. The material affects mold life, part quality, and cost. It also affects how fast and how often a mold can run. In this article, we’ll explore the best tooling materials. We’ll also look at how a Mold […]

The Best Tooling Materials for Electronic Injection Molding Read More »