Cost Management in Manufacturing: Why Injection Mould Companies Matter

Look, if you’re in manufacturing, cost management isn’t just a nice-to-have—it’s survival. And when it comes to plastics, an injection mould company is your ride-or-die for keeping expenses under control. Ignore this, and you might as well toss your budget in a shredder.

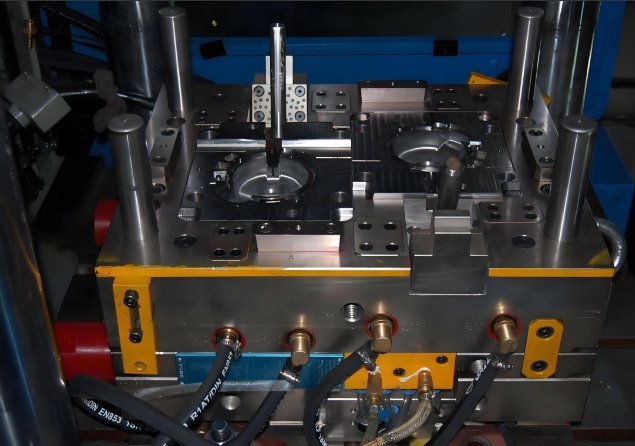

Mold Maker Know-How: The First (and Most Crucial) Step

Everything starts with the mold design. Trust your mold maker, because if they mess this up, you’re doomed from the get-go. A great mold maker will obsess over every detail, making sure your mold is spot-on so your parts come out right. Don’t be cheap here—cutting corners at this stage is like building a house on sand.

Material Costs: Steel vs. Aluminum (Don’t Just Flip a Coin)

Let’s talk materials. Steel molds are the tanks of the injection mould company world—expensive but built to last. Aluminum molds are cheaper and work fine for shorter runs. Any experienced mold maker will tell you: pick your material based on your production goals. High volume? Go steel. Just testing the waters? Aluminum’s your friend.

Production Costs: It’s All About the Details

Production costs depend on the size of your part, the type of plastic, and how fast your machines can crank stuff out. Some plastics, like polypropylene, are wallet-friendly, while others (PEEK, I’m looking at you) will make your accountant sweat. A sharp injection mould company knows how to tweak cycle times and machine settings to save you dough without sacrificing quality.

Maintenance: The Dirty Secret No One Wants to Talk About

Here’s the thing—molds need love. Skip maintenance, and your mold will throw tantrums (read: breakdowns and ugly parts). Regular checkups by a skilled mold maker keep things humming and cut down on pricey repairs later.

Labor and Automation: Finding the Sweet Spot

Labor isn’t free, and neither are robots. A good injection mould company knows when to use their people and when to let machines do the heavy lifting. Automation can save big bucks, but only if you’re ready for the upfront investment.

Shipping and Logistics: Don’t Let Costs Sneak Up

Even the best parts in the world mean nothing if you can’t ship them on time. Lightweight plastics keep freight bills sane, but those big, beefy molds? Yeah, you’ll need a reliable logistics plan—and a mold maker who knows how to pack and ship without drama.

How an Injection Mould Company Saves You Money

Standardized Mold Designs: Cut the Fluff

Standard molds = less time, less money. A smart mold maker will use modular designs that work across projects, so you’re not shelling out for a new mold every time.

Efficient Use of Materials: Waste Not, Want Not

An injection mould company worth their salt will push for hot-runner systems, optimized machine settings, and even recycled plastics. All these moves keep material costs in check and make you look good for being “green.”

Batch Production: Bigger is Cheaper

Want to pay less per part? Crank out more at once. It’s not rocket science, just basic math.

Energy Efficiency: Lower Bills, Fewer Regrets

Modern machines from a forward-thinking injection mould company use less juice. Energy bills drop, profits go up. Easy win.

Outsourcing to a Mold Maker: Focus on What You Do Best

Why try to be a mold expert when you can just hire one? Outsourcing to an injection mould company gets you pro-level design, production, and quality control—without the expense of building your own team.

Preventive Maintenance: Save Now, Smile Later

A little TLC from your mold maker keeps the wheels turning and means fewer nasty surprises. Trust me, you want this.

Supply Chain Smarts: Don’t Let Delays Destroy You

A solid injection mould company works with reliable suppliers so you’re not left waiting around. Streamlined logistics mean fewer headaches and more cash in your pocket.

Long-Term Contracts: Lock in the Savings

Sign on for the long haul and snag those bulk discounts. A good injection mould company will work with you for better rates and more predictable costs.

Quality Molds: Pay Upfront, Save Long-Term

Invest in a top-notch mold from a seasoned mold maker. It’ll last longer and produce fewer duds, which means less waste and more wins.

Future-Proofing: What’s Next for Injection Mould Companies?

Tech is moving fast. Automation, AI, and smarter machines are changing the game. Any injection mould company that stays ahead will help you cut costs in ways you haven’t even thought of yet.