Automotive injection molds are essential in vehicle manufacturing. They shape plastic parts used in cars. These molds ensure accuracy, durability, and efficiency. Every car has multiple plastic components. Each part requires a unique mold. A skilled mold maker ensures high-quality production. The automotive industry relies on precise molding for safety and performance.

Why Automotive Injection Molds Matter

Automotive injection molds are crucial for mass production. They create parts with consistency. Every detail must be exact. Any defect can affect vehicle performance. A well-made mold reduces errors. It ensures that all parts fit perfectly. Mold makers must maintain precision in every step.

The Role of a Mold Maker in the Automotive Industry

A mold maker plays a key role in automotive manufacturing. They design, build, and test molds. Their expertise ensures that parts meet industry standards. Mold makers work with engineers to develop innovative solutions. They use advanced tools to create complex molds. Their work requires precision, skill, and experience.

Types of Automotive Injection Molds

There are different types of automotive injection molds. Each serves a specific function. The main types include:

1. Interior Component Molds

These molds create dashboards, door panels, and consoles. They must have smooth finishes and fine details.

2. Exterior Component Molds

Used for bumpers, grilles, and side mirrors. These molds must withstand harsh conditions.

3. Engine and Under-the-Hood Molds

These molds shape air ducts, battery covers, and fluid reservoirs. They require heat-resistant materials.

4. Lighting Component Molds

Used for headlights, taillights, and indicator covers. They must be transparent and durable.

The Mold Making Process

Creating automotive injection molds involves several steps. Each step requires accuracy.

1. Design and Planning

Engineers create a 3D model of the mold. The design must be perfect before production starts.

2. Material Selection

A mold maker chooses high-quality materials. Steel and aluminum are common choices. The material must handle high pressure and temperature.

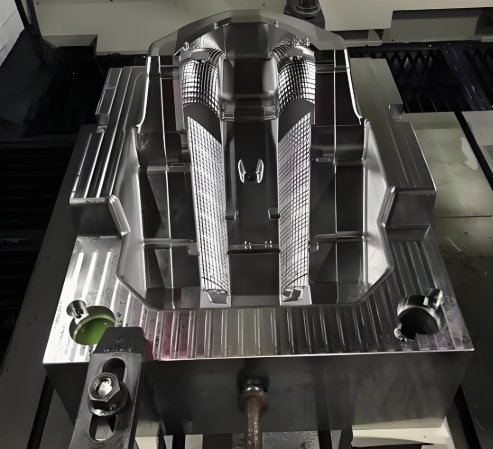

3. CNC Machining

The mold is cut and shaped using CNC machines. Precision is key at this stage.

4. Heat Treatment

This process strengthens the mold. It improves durability and longevity.

5. Polishing and Assembly

The mold is polished for a smooth finish. All parts are assembled for final testing.

6. Testing and Quality Control

The mold is tested to ensure accuracy. Any defects are corrected before production.

Materials Used in Automotive Injection Molds

Different materials are used based on requirements.

1. Steel Molds

Steel is strong and durable. It lasts for high-volume production.

2. Aluminum Molds

Aluminum is lightweight and cost-effective. It is used for low-volume production.

3. Hybrid Molds

A combination of steel and aluminum. It balances durability and cost.

Common Challenges in Mold Making

A mold maker faces many challenges.

1. High Precision Requirements

Every mold must be exact. Even small errors cause defects.

2. Long Production Times

Making automotive injection molds takes time. Each step must be carefully executed.

3. Cost of Materials

High-quality materials are expensive. Mold makers must balance cost and quality.

4. Maintaining Consistency

Every mold must produce identical parts. Any variation leads to defects.

Innovations in Automotive Injection Molds

New technologies improve mold-making processes.

1. 3D Printing for Prototypes

3D printing speeds up mold design. It allows quick testing before production.

2. Advanced CNC Machining

Faster and more precise cutting tools improve mold accuracy.

3. Automation in Mold Making

Robots help speed up production. They reduce human errors.

4. Sustainable Mold Materials

Recyclable materials reduce waste. They make molding more eco-friendly.

The Future of Mold Makers in the Automotive Industry

The demand for automotive injection molds is growing. More cars mean more molds. Mold makers must keep up with trends. Electric vehicles require new types of molds. Lightweight materials are becoming more common. Automation will play a bigger role in production.

Automotive injection molds are key to vehicle manufacturing. They ensure precision and efficiency. A skilled mold maker plays a vital role. They design, build, and test molds to perfection. Innovations continue to improve mold-making processes. As the industry evolves, so will mold makers. Their expertise will shape the future of automotive production.