The healthcare industry relies on innovation. Medical injection molding has changed how medical devices are made. Mold makers create precise, reliable components. This technology has improved efficiency, safety, and affordability.

1. The Role of Medical Injection Molding in Healthcare

1.1 High Precision Manufacturing

- Produces small, detailed medical parts.

- Ensures uniformity in mass production.

- Reduces human error in medical device production.

1.2 Cost-Effective Production

- Lowers material waste.

- Supports high-speed manufacturing.

- Reduces labor costs through automation.

1.3 Meeting Medical Standards

- Ensures compliance with FDA and ISO regulations.

- Allows for sterilization-friendly materials.

- Guarantees biocompatibility for patient safety.

2. Key Medical Devices Made with Injection Molding

2.1 Syringes and IV Components

- High-volume production at low cost.

- Disposable and contamination-free.

- Used in hospitals worldwide.

2.2 Surgical Instruments

- Precise scalpels, forceps, and retractors.

- Made with high-strength medical plastics.

- Ensures durability and sterilization safety.

2.3 Implantable Devices

- Pacemaker casings and orthopedic implants.

- Requires biocompatible plastics.

- Ensures long-term patient safety.

2.4 Diagnostic Equipment

- Components for test kits and lab devices.

- Improves testing accuracy.

- Supports mass production for global needs.

3. The Role of Mold Makers in Healthcare Innovation

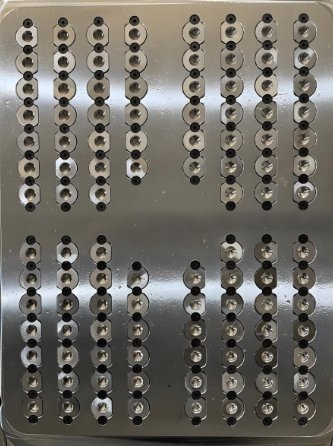

3.1 Designing Complex Molds

- Creates detailed, intricate shapes.

- Supports micro-molding for tiny components.

- Ensures flawless precision in medical parts.

3.2 Material Selection

- Uses medical-grade plastics.

- Ensures heat, chemical, and impact resistance.

- Selects materials based on sterilization needs.

3.3 Maintaining Quality Control

- Uses automated inspection systems.

- Reduces defects in mass production.

- Meets strict healthcare regulations.

4. Advantages of Medical Injection Molding Over Traditional Methods

4.1 Faster Production Cycles

- Produces thousands of parts per hour.

- Reduces lead times for medical device manufacturing.

- Speeds up delivery of life-saving equipment.

4.2 Consistent Product Quality

- Ensures exact replication of each component.

- Reduces variations in medical devices.

- Enhances patient safety and device reliability.

4.3 Enhanced Design Flexibility

- Creates customized solutions for medical needs.

- Allows for lightweight, ergonomic designs.

- Supports innovation in wearable healthcare devices.

5. Cutting-Edge Innovations in Medical Injection Molding

5.1 Micro Molding for Miniature Devices

- Used for tiny surgical implants.

- Improves precision in delicate procedures.

- Enables minimally invasive treatments.

5.2 Overmolding for Multi-Material Components

- Combines soft and hard materials.

- Improves grip and comfort in medical tools.

- Enhances durability and usability.

5.3 Automation for High-Volume Production

- Reduces human error.

- Increases efficiency in large-scale manufacturing.

- Supports continuous production without downtime.

6. Real-World Success Stories

6.1 Revolutionizing Diabetes Care

- Insulin pens made using medical injection molding.

- Ensures accurate dosing and easy handling.

- Helps millions of diabetic patients worldwide.

6.2 Advanced Pacemaker Casings

- Needed strong, lightweight materials.

- Injection molding created biocompatible casings.

- Improved patient comfort and safety.

6.3 High-Speed COVID-19 Test Kit Production

- Demand surged for rapid tests.

- Mold makers helped scale production.

- Millions of kits were delivered worldwide.

7. The Future of Medical Injection Molding

7.1 Smart Medical Devices

- Wearable health monitors.

- Miniature sensors for real-time tracking.

- Supports remote healthcare solutions.

7.2 Sustainable Medical Plastics

- Development of biodegradable materials.

- Reducing medical waste in hospitals.

- Meeting eco-friendly goals.

7.3 AI-Driven Production Optimization

- Predicts defects before production.

- Reduces material waste and costs.

- Enhances production speed and accuracy.

Medical injection molding has transformed healthcare. Mold makers ensure precision and innovation. This technology creates life-saving devices. It will continue shaping the future of medicine.