Designing Molds for High-Precision Electronic Components

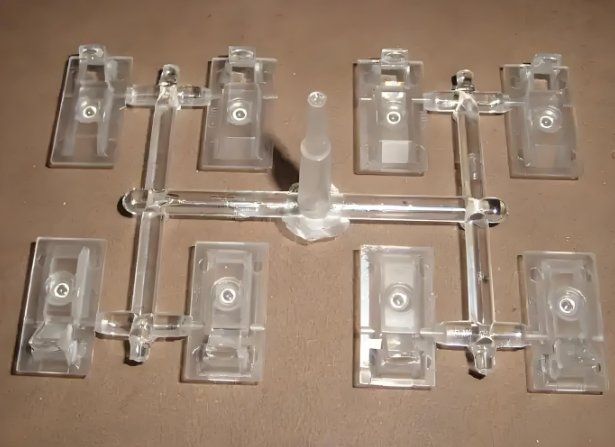

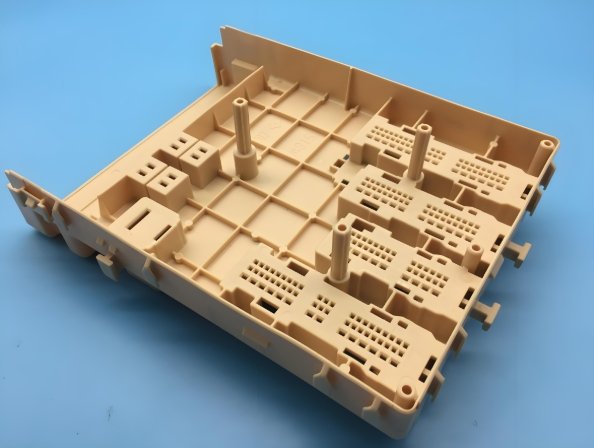

In Electronic Injection Molding, accuracy is everything. Parts must fit perfectly. Small errors can cause big problems. That’s why precision mold design is so important. A skilled Mold Maker makes it possible. Why Precision Matters in Electronics Electronic parts are small. Very small. Even tiny size errors can cause failure. Precision ensures that each molded […]

Designing Molds for High-Precision Electronic Components Read More »