utomotive injection molds play a vital role in the automotive industry. These molds are used to create parts that are essential for vehicles. Automotive injection molds are made using high-quality materials. They ensure precision and strength in automotive components. Every part is carefully designed to meet industry standards. Mold makers use advanced techniques to produce these molds. They are crucial for mass production and high efficiency.

The Importance of Automotive Injection Molds

Automotive injection molds are used to create plastic parts in vehicles. These parts range from bumpers to dashboards. Each part requires a different mold. The mold must be durable and able to withstand high pressure. Mold makers must ensure that the molds meet the required specifications. The molds must also allow for fast production times. Fast production is key to meeting the global demand for automotive parts.

How Automotive Injection Molds Are Made

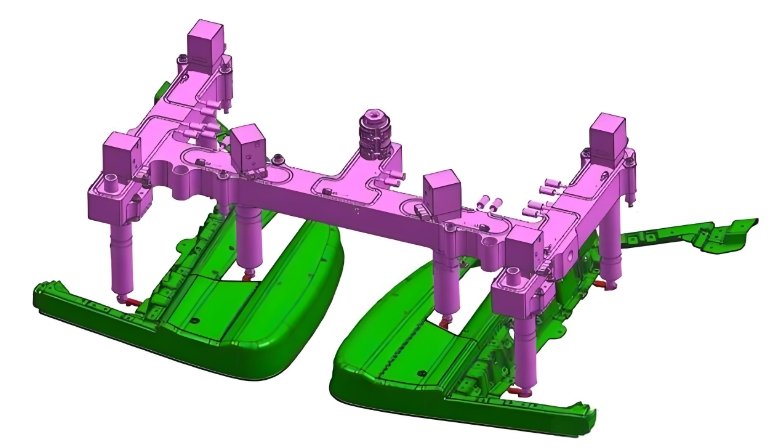

The process of making automotive injection molds starts with designing the mold. Engineers use CAD software to create precise designs. Then, the mold maker selects the material for the mold. The material must be strong and able to handle the heat and pressure during molding. Afterward, the mold is created using high-precision machines. The mold is tested and adjusted to ensure it works perfectly. The process is very detailed. Small errors can lead to big problems. Mold makers must ensure that every mold is flawless.

The Role of Mold Makers in the Automotive Industry

Mold makers are at the heart of the automotive industry. Without them, the production of high-quality automotive parts would be impossible. Mold makers work closely with engineers to ensure that every part is made to perfection. They are experts in using machinery and tools to create molds. They also know how to troubleshoot any issues that arise during production. Their job is not just to create molds but to innovate. Mold makers are constantly looking for ways to improve production efficiency and reduce costs.

Applications of Automotive Injection Molds

The applications of automotive injection molds are vast. They are used to create a wide range of parts for vehicles. These parts include exterior and interior components. Some examples include door panels, mirrors, and grilles. Automotive injection molds are also used for engine parts, fuel tanks, and lighting components. The molds allow for precise shaping and forming of materials. This precision is critical for ensuring the safety and quality of automotive parts.

The Advantages of Automotive Injection Molds

Automotive injection molds have many advantages. One of the main benefits is cost-effectiveness. Injection molding is an efficient process that reduces production time. It also reduces material waste. The molds allow for high-volume production. This means that manufacturers can meet the growing demand for automotive parts. Another advantage is the ability to create complex shapes. Mold makers can create detailed parts with intricate designs. This is especially important in the automotive industry, where parts often have complex shapes.

Quality Control in Automotive Injection Molds

Quality control is essential in the production of automotive injection molds. Every mold must meet strict standards to ensure the parts are safe and functional. The molds are tested at each stage of production. Mold makers inspect the molds for any defects or issues. They also perform stress tests to ensure the parts will perform well under pressure. Quality control helps prevent costly mistakes and ensures that the end product is of the highest quality.

Global Markets and the Demand for Automotive Injection Molds

The demand for automotive injection molds is growing in global markets. The automotive industry is expanding in many countries. As new technologies emerge, the demand for high-quality parts increases. Manufacturers need to keep up with this demand. They require mold makers who can produce molds quickly and efficiently. The global automotive market is competitive. To stay ahead, manufacturers must rely on advanced molding techniques and high-quality molds.

Challenges Faced by Mold Makers

While mold makers play a crucial role, they also face challenges. One of the biggest challenges is the need for constant innovation. The automotive industry is always changing. New technologies and materials require mold makers to adapt quickly. Another challenge is the high cost of advanced machinery and materials. Mold makers must invest in cutting-edge technology to stay competitive. Additionally, they must ensure that their molds are capable of handling the growing demand for automotive parts.

Sustainability in Automotive Injection Molds

Sustainability is becoming a key factor in the production of automotive injection molds. Manufacturers are looking for ways to reduce waste and energy consumption. Mold makers are finding ways to use recycled materials in their molds. They are also designing molds that use less energy during production. These efforts help make the automotive industry more environmentally friendly.

The Future of Automotive Injection Molds

The future of automotive injection molds looks bright. As the automotive industry continues to grow, so will the demand for high-quality molds. New technologies, such as electric vehicles, will require even more advanced molding techniques. Mold makers will continue to innovate to meet these new challenges. The future of automotive manufacturing will rely heavily on the expertise of mold makers and the technology they use.

In conclusion, automotive injection molds are a critical component of the automotive industry. They ensure that high-quality parts are produced quickly and efficiently. Mold makers play an essential role in this process. They are responsible for creating molds that meet strict quality standards. The demand for automotive injection molds will continue to grow as the global automotive market expands. As the industry evolves, mold makers will continue to innovate to meet the needs of the future. The role of mold makers will be more important than ever in the years to come.