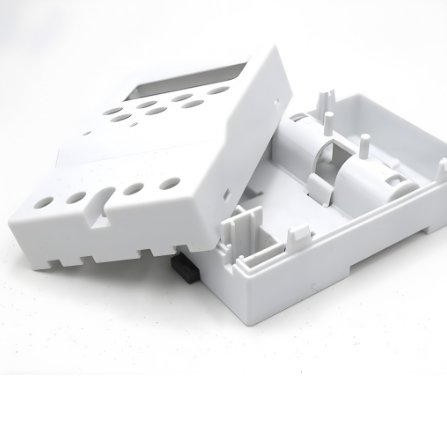

Custom Mold Designs for Unique Electronic Products

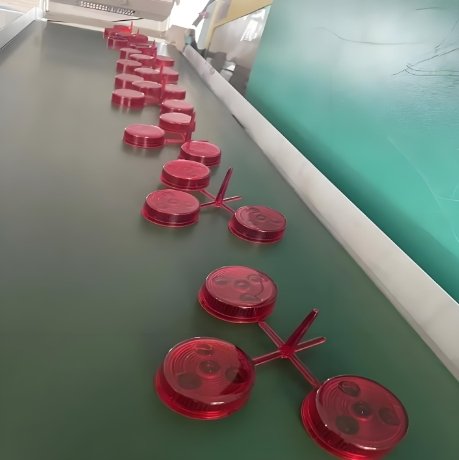

In Electronic Injection Molding, every product is different.Every design has its own challenges.Some electronic products need special molds.A custom mold ensures precision and quality.A good Mold Maker knows how to create molds that meet these needs. Let’s look at the role of custom molds in Electronic Injection Molding. Why Custom Molds Are Essential for Electronics […]

Custom Mold Designs for Unique Electronic Products Read More »