How to Avoid Flash in Electronic Injection Molding

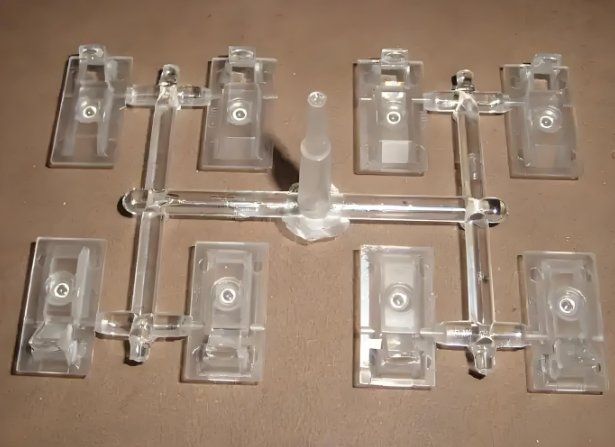

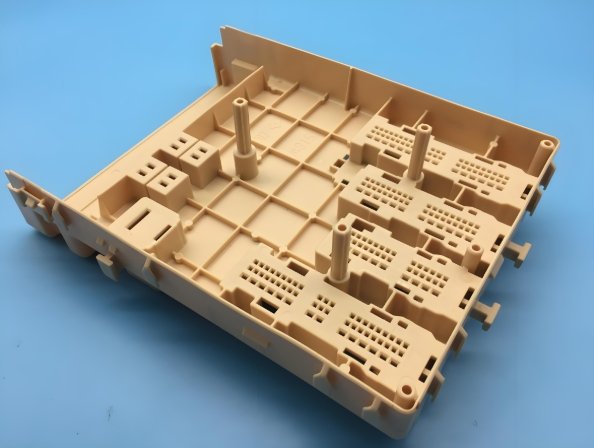

Electronic Injection Molding is key to making strong and precise electronic parts. But flash is a big problem. Flash is the extra plastic that leaks out of the mold. It forms thin fins on the part’s edges. Flash looks bad. It also affects part size and function. Let’s learn how to stop it. A smart […]

How to Avoid Flash in Electronic Injection Molding Read More »