The Role of Robotics in Electronic Injection Molding

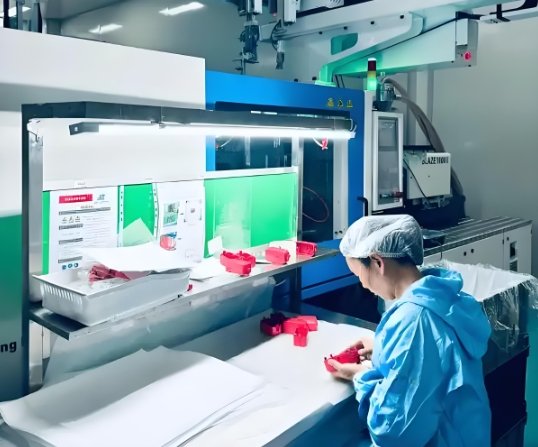

Automation is changing manufacturing. Electronic injection molding relies on robotics for precision. A skilled mold maker integrates advanced systems for better efficiency. This article explores how robotics is shaping the future of molding. 1. Why Robotics is Important in Injection Molding 1.1 Enhancing Precision Robots work with extreme accuracy. Electronic injection molding benefits from reduced […]

The Role of Robotics in Electronic Injection Molding Read More »