Injection Molding for Advanced Automotive Structures

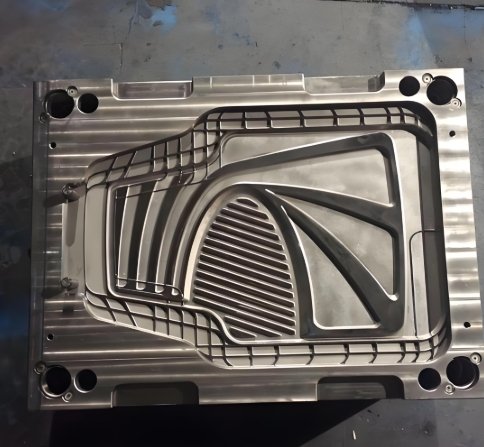

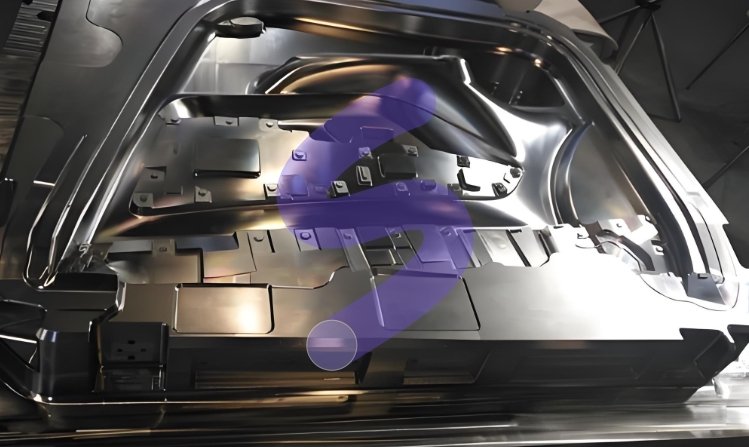

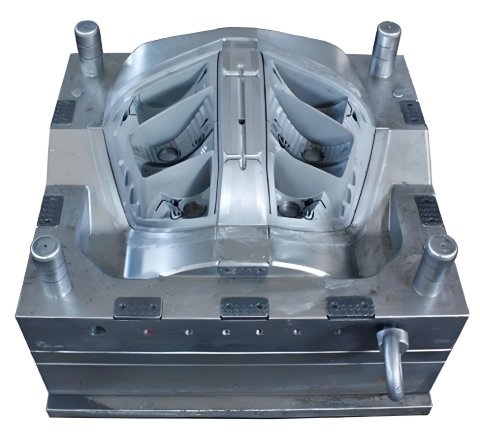

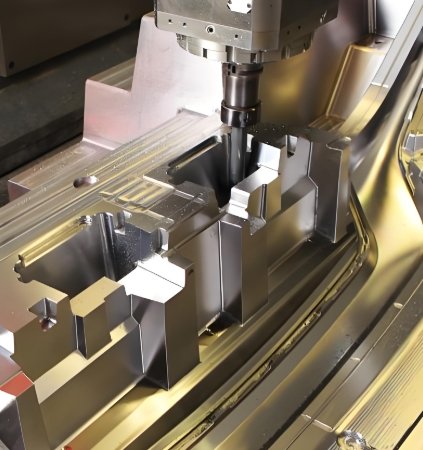

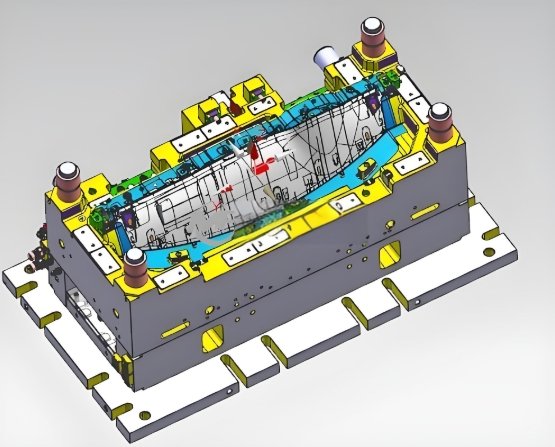

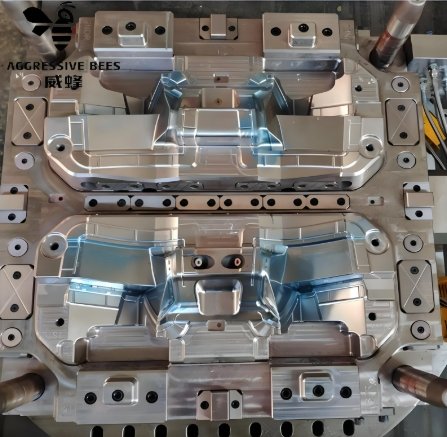

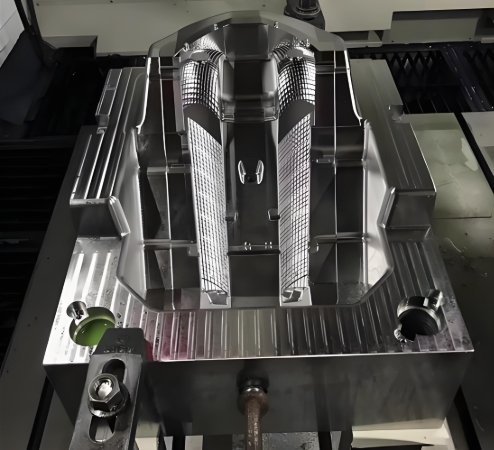

Injection molding plays a crucial role in the development of advanced automotive structures. Automotive Injection Molds are used to create parts that offer high strength and precision. These parts must meet strict safety standards and perform well in demanding environments. Skilled Mold Makers are essential in ensuring the parts are both functional and durable. This […]

Injection Molding for Advanced Automotive Structures Read More »