Injection Molding vs. CNC for Housing Parts

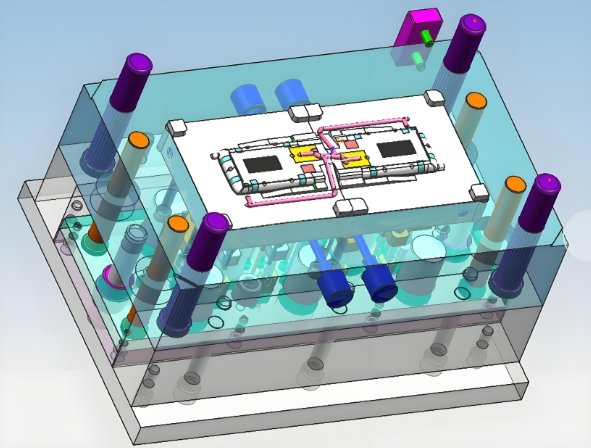

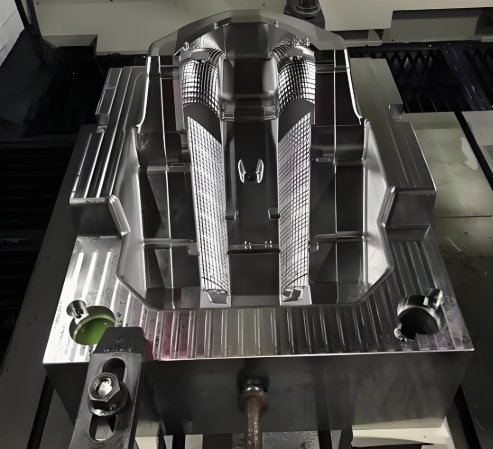

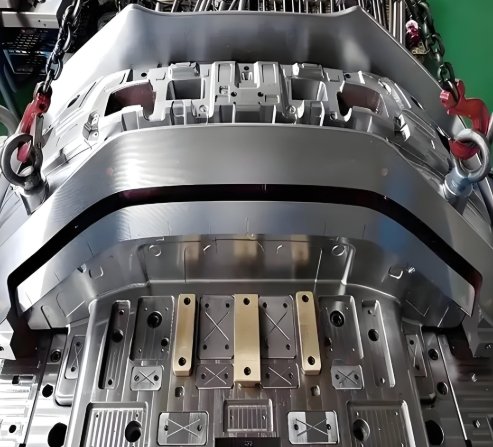

Making the Right Choice with Housing Injection Molding and Expert Mold Maker Support In the world of plastic product manufacturing, two common methods stand out: housing Injection Molding and CNC machining. Each has its strengths, but they serve different goals. If you’re creating housings for electronic devices, tools, medical equipment, or battery packs, you need […]