Modern vehicles require precision. Automotive injection molds create essential plastic parts. These parts improve performance, durability, and safety. A skilled mold maker ensures accuracy in every component. Custom mold designs enhance efficiency and innovation in automotive manufacturing.

Why Custom Automotive Injection Molds Matter

Every car model has unique parts. Automotive injection molds must match exact specifications. Custom molds allow automakers to create specialized components. A professional mold maker ensures perfect fit and function. This guarantees high performance and safety.

Key Benefits of Custom Injection Molds

1. Precision Engineering

Custom molds meet tight tolerances. Every part fits perfectly.

2. Enhanced Durability

High-quality materials extend part lifespan. Vehicles become more reliable.

3. Lightweight Components

Plastic parts reduce overall weight. This improves fuel efficiency.

4. Cost-Effective Production

Injection molding allows mass production. Costs remain low while quality stays high.

5. Faster Manufacturing

Automated molding speeds up production. Custom designs ensure efficiency.

Custom Mold Applications in Automotive Manufacturing

1. Interior Components

Dashboards, center consoles, and air vents need precision. Custom molds create seamless finishes.

2. Exterior Parts

Bumpers, grilles, and side mirrors require durability. Automotive injection molds ensure impact resistance.

3. Under-the-Hood Components

Engine covers, battery casings, and fluid reservoirs need heat resistance. Custom molds improve performance.

4. Advanced Safety Features

Airbag housings, seatbelt clips, and sensor casings require strong materials. A mold maker ensures reliability.

5. Electric Vehicle Parts

Battery enclosures and charging ports need exact measurements. Injection molds guarantee accuracy.

The Role of a Mold Maker in Custom Designs

A mold maker transforms concepts into reality. Custom designs need expert craftsmanship. Every mold must meet strict industry standards.

1. Design and Development

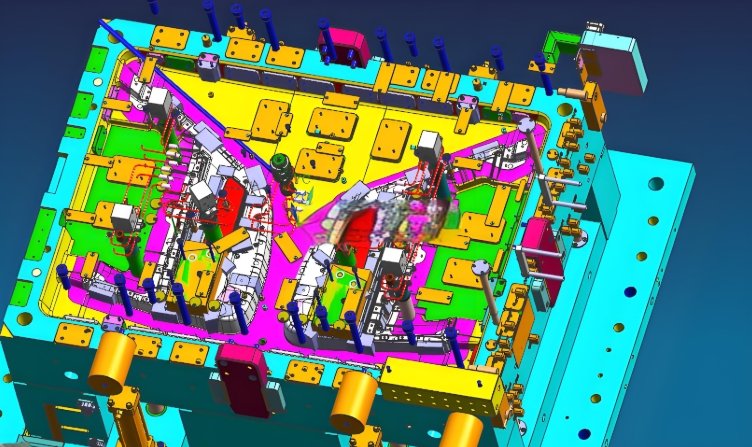

Engineers create 3D models. These designs ensure a perfect match for each vehicle part.

2. Material Selection

High-performance plastics improve strength and durability. A mold maker chooses the best material for each part.

3. CNC Machining for Precision

CNC machines cut molds with extreme accuracy. This guarantees perfect results.

4. Quality Control

Each mold undergoes rigorous testing. This prevents defects and ensures flawless production.

Different Types of Custom Automotive Injection Molds

1. Single-Cavity Molds

These molds create one part at a time. They are used for precision manufacturing.

2. Multi-Cavity Molds

These molds produce multiple parts in one cycle. They improve efficiency.

3. Hot Runner Molds

These molds reduce waste and speed up production. They are ideal for high-volume manufacturing.

4. Overmolding

This process combines multiple materials. It enhances grip and durability.

5. Insert Molding

Plastic is molded around metal inserts. This strengthens the final part.

Challenges in Custom Automotive Mold Making

1. Complex Designs

Custom molds require detailed engineering. A skilled mold maker ensures precision.

2. Material Compatibility

Different plastics react differently under heat and pressure. Choosing the right material is crucial.

3. High Production Standards

Every mold must meet industry regulations. Even small defects can lead to failure.

4. Cost Management

Custom molds require investment. However, they save money in mass production.

5. Rapid Technological Changes

Automotive trends evolve fast. Mold makers must adapt to new designs.

Innovations in Automotive Injection Molds

1. 3D Printing for Prototyping

Rapid prototyping reduces development time. Engineers can test new designs quickly.

2. AI-Powered Mold Design

Artificial intelligence optimizes mold geometry. This improves efficiency.

3. Sustainable Materials

Eco-friendly plastics reduce environmental impact. The industry moves toward greener solutions.

4. Automation in Manufacturing

Robotic systems increase accuracy. They also reduce human error.

How Custom Injection Molds Improve Vehicle Manufacturing

1. Faster Production Cycles

Custom molds allow rapid part creation. This speeds up vehicle assembly.

2. Higher Quality Standards

Every part meets the same specifications. This ensures consistency.

3. Cost Savings in Mass Production

Custom molds may be expensive upfront. However, they reduce costs in large-scale manufacturing.

4. Improved Vehicle Performance

Lightweight and durable parts enhance efficiency. Vehicles become safer and more reliable.

Future of Custom Mold Making in the Automotive Industry

Custom automotive injection molds continue to evolve. Electric and autonomous vehicles require advanced molding techniques. A skilled mold maker plays a key role in future developments. The demand for precision and innovation grows every year.

Custom automotive injection molds shape the future of vehicle manufacturing. They ensure precision, durability, and efficiency. A professional mold maker designs molds that meet exact automotive standards. As technology advances, custom molds will play an even bigger role in automotive excellence.