Automotive parts require precision and speed. Automotive injection molds make high-volume production possible. A skilled mold maker ensures quality and efficiency.

Why High-Volume Production Matters

1. Faster Manufacturing

Speed is critical in the auto industry. Automotive injection molds produce thousands of parts quickly. A mold maker ensures rapid cycles.

2. Cost Reduction

Mass production lowers costs. Automotive injection molds reduce material waste. A mold maker optimizes designs for efficiency.

3. Consistent Quality

Every part must be identical. Automotive injection molds maintain precision. A mold maker ensures accurate molds.

4. Meeting Industry Demand

The auto industry requires millions of parts. Automotive injection molds support high demand. A mold maker helps manufacturers scale up.

Materials for High-Volume Injection Molding

1. ABS (Acrylonitrile Butadiene Styrene)

ABS is strong and lightweight. Automotive injection molds use ABS for dashboards and trims. A mold maker ensures perfect finishes.

2. Polypropylene (PP)

PP is flexible and impact-resistant. Automotive injection molds use PP for interior panels. A mold maker selects PP for durability.

3. Polycarbonate (PC)

PC withstands heat and pressure. Automotive injection molds use PC for headlights. A mold maker ensures high clarity and strength.

4. Nylon (PA)

Nylon is wear-resistant. Automotive injection molds use nylon for gears and under-hood parts. A mold maker ensures precision in complex shapes.

Key Processes in High-Volume Injection Molding

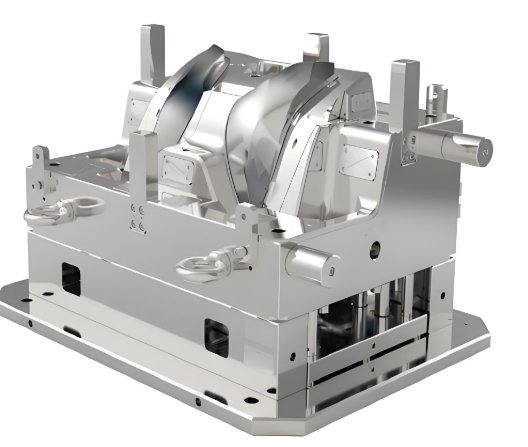

1. Mold Design and Engineering

A good mold ensures quality. Automotive injection molds need exact specifications. A mold maker uses CAD software for precise designs.

2. Material Selection

Choosing the right plastic is crucial. Automotive injection molds must handle high stress. A mold maker selects materials for strength and flexibility.

3. Injection Molding Process

Molten plastic is injected into the mold. Automotive injection molds shape parts under high pressure. A mold maker ensures even distribution.

4. Cooling and Ejection

Cooling prevents defects. Automotive injection molds must have efficient cooling channels. A mold maker optimizes cooling for fast cycles.

5. Finishing and Quality Control

Parts need a smooth surface. Automotive injection molds create precise shapes. A mold maker inspects for defects before shipping.

Advantages of High-Volume Injection Molding

1. Fast Production Cycles

Molding is quicker than other methods. Automotive injection molds allow high-speed manufacturing. A mold maker fine-tunes the process for efficiency.

2. Lower Cost Per Part

Bulk production saves money. Automotive injection molds reduce labor costs. A mold maker designs molds for high output.

3. Minimal Material Waste

Optimized designs use less plastic. Automotive injection molds minimize scrap. A mold maker refines gates and runners to reduce excess.

4. Enhanced Precision

Tight tolerances matter. Automotive injection molds ensure exact dimensions. A mold maker maintains high accuracy in every part.

Challenges in High-Volume Production

1. Mold Wear and Tear

Frequent use damages molds. Automotive injection molds must be durable. A mold maker uses hardened steel for longevity.

2. Heat Management

High-speed production generates heat. Automotive injection molds need proper cooling. A mold maker optimizes cooling channels for efficiency.

3. Defects and Inconsistencies

Air bubbles and warping can occur. Automotive injection molds must be flawless. A mold maker tests molds for accuracy.

4. Cost of High-Quality Molds

Precision molds are expensive. Automotive injection molds require advanced tooling. A mold maker balances cost and performance.

Innovations in High-Volume Injection Molding

1. Multi-Cavity Molds

More cavities mean more parts per cycle. Automotive injection molds now use multi-cavity designs. A mold maker creates complex layouts for efficiency.

2. Automated Production

Robots improve speed and accuracy. Automotive injection molds now integrate automation. A mold maker programs machines for precision.

3. 3D Printing for Prototyping

Prototyping speeds up design. Automotive injection molds benefit from 3D-printed samples. A mold maker tests new designs before full production.

4. Smart Sensors in Molds

Sensors detect defects early. Automotive injection molds now have built-in monitoring. A mold maker uses data to optimize performance.

Future of High-Volume Injection Molding

1. Faster Cycle Times

Machines are getting faster. Automotive injection molds will soon have even quicker cycles. A mold maker improves efficiency with new designs.

2. Sustainable Materials

Recyclable plastics are the future. Automotive injection molds will use eco-friendly materials. A mold maker explores biodegradable options.

3. AI-Optimized Molding

Artificial intelligence improves production. Automotive injection molds will use AI for defect detection. A mold maker will rely on data for better results.

4. Lightweight Components

Automakers want lighter parts. Automotive injection molds will focus on weight reduction. A mold maker selects advanced composites for strength.

High-volume production keeps the auto industry moving. Automotive injection molds make mass manufacturing efficient. A skilled mold maker ensures precision, durability, and cost savings. Future innovations will push injection molding even further.