Precision is everything in electronic components. Electronic injection molding requires high accuracy to ensure parts fit, function, and last. Small tolerances and fine details can make a huge difference. A mold maker uses advanced techniques to ensure each part is made with perfect precision.

1. Understanding Precision in Electronic Injection Molding

1.1 What is Precision in Injection Molding?

Precision in injection molding means making parts that match the design exactly. Every small detail, from shape to size, must be consistent. This is especially important for electronics where small deviations can cause malfunctions.

1.2 Why Precision Matters in Electronics

Electronics require accurate dimensions. Even a small error can lead to poor performance, such as loose connections or overheating. Precision ensures that each part interacts perfectly with others in the system.

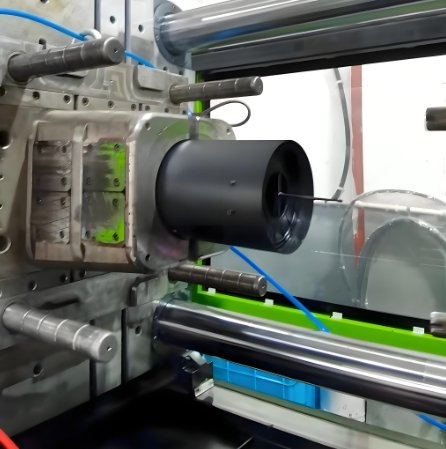

1.3 The Role of a Mold Maker

A mold maker is responsible for creating the mold that shapes these parts. They must account for materials, design, and injection pressure to ensure that the final product matches the intended design.

2. Key Factors Affecting Precision in Electronic Injection Molding

2.1 Material Choice

The material used in injection molding affects the final part’s precision. Some materials shrink more than others when cooled, which can lead to dimensional changes. Mold makers must choose materials with low shrinkage rates for greater precision.

2.2 Mold Design

The mold design plays a critical role in achieving high precision. A mold must be carefully crafted with tight tolerances. The mold cavity must be smooth and defect-free to ensure a consistent part.

2.3 Injection Pressure

The pressure at which the plastic is injected into the mold affects the final product’s precision. Too much pressure can cause distortion, while too little can result in incomplete parts. Mold makers carefully control injection pressure for optimal results.

2.4 Cooling Time

Cooling is a critical step in the injection molding process. If parts cool unevenly, they can warp. Mold makers use precise cooling channels to ensure uniform cooling and avoid defects.

2.5 Cycle Time

Cycle time is the duration from injecting the material to ejecting the molded part. Shorter cycle times are generally desired but must be balanced with quality. A mold maker must optimize cycle time to ensure both efficiency and precision.

3. Techniques to Achieve High Precision

3.1 Multi-Cavity Molds

Multi-cavity molds allow multiple parts to be produced simultaneously. This reduces production time and ensures that all parts are identical. Precision is crucial in multi-cavity molds to avoid variations between parts.

3.2 Micro-Molding

Micro-molding involves creating tiny parts with intricate details. It’s often used in electronics where components are small and precise. A mold maker must use high-precision machinery to achieve the necessary accuracy in micro-molding.

3.3 Hot Runner Systems

Hot runner systems keep the material at a constant temperature while it flows into the mold. This ensures that the material fills the cavity evenly and accurately. Hot runners reduce waste and improve precision by maintaining a consistent flow of material.

3.4 High-Precision Molding Machines

The machinery used for molding affects the precision of the parts. Modern high-precision injection molding machines can control temperature, pressure, and speed to an incredible degree. These machines are essential for achieving high-quality electronic components.

3.5 Fine-Tuning Mold Design

Mold makers continuously fine-tune the mold design to improve precision. This can involve adjusting the size of the mold cavity or adding features like cooling channels to reduce warping. The goal is to achieve a perfect fit and finish.

3.6 Using Advanced Simulation Software

Advanced simulation software helps mold makers visualize how the plastic will behave inside the mold. By simulating the molding process, potential problems like air pockets, uneven cooling, or shrinkage can be identified and corrected before production begins.

3.7 Opting for Low-Shrinkage Materials

Low-shrinkage materials are essential for achieving tight tolerances. These materials shrink less as they cool, reducing the chance of dimensional changes. Choosing the right material helps maintain precision in the final part.

3.8 Using Secondary Operations

In some cases, secondary operations like CNC machining or laser engraving are used after molding to further refine the part. These processes can be used to add fine details, improve the surface finish, or adjust dimensions to meet the required specifications.

4. The Challenges of Achieving Precision

4.1 Material Variability

Different batches of material can behave slightly differently. Even small variations can affect the precision of the molded parts. Mold makers must account for these differences and adjust their processes accordingly.

4.2 Part Complexity

As electronic components become more complex, achieving precision becomes more challenging. Tiny parts with intricate features, such as connectors or circuit board housings, require the highest level of accuracy.

4.3 Tooling Wear

Over time, molds can wear out. The wear and tear on the tooling can cause slight changes in the molded part’s dimensions. Regular maintenance and periodic replacement of tools help maintain precision over the long term.

4.4 Temperature Control

Temperature fluctuations can lead to inconsistent results. Mold makers must monitor and control the temperature of the mold and material throughout the injection molding process to ensure that the parts meet the required specifications.

5. Benefits of High Precision in Electronic Injection Molding

5.1 Better Performance

Precise components ensure that electronics function as intended. Accurate connections, seals, and enclosures prevent malfunctions and enhance the overall performance of the device.

5.2 Reduced Waste

High precision reduces the number of defective parts produced. This results in less material waste and lower production costs.

5.3 Cost Efficiency

While achieving high precision requires careful planning and execution, it can lead to lower costs in the long run. Fewer defective parts mean less rework and fewer material costs.

5.4 Enhanced Durability

Parts made with high precision are more durable. They fit better, perform more reliably, and are less likely to experience wear or failure during use.

5.5 Improved Aesthetics

Precise molding results in better-looking parts. Fine details, smooth surfaces, and sharp edges all contribute to the overall aesthetic quality of the product.

6. The Future of High-Precision Injection Molding in Electronics

6.1 Advancements in Materials

New materials with improved properties are being developed for high-precision injection molding. These materials will provide better durability, heat resistance, and electrical properties for electronics.

6.2 Automation and AI Integration

Automation and AI will play an increasing role in high-precision molding. Smart machines will monitor and adjust the molding process in real-time, ensuring even greater accuracy and consistency.

6.3 3D Printing for Rapid Prototyping

3D printing allows for rapid prototyping of molds. This will enable mold makers to test their designs quickly and make necessary adjustments before committing to full-scale production.

6.4 Integration with IoT

As IoT devices become more common, the demand for precise, small components will grow. Electronic injection molding will continue to evolve to meet the needs of these advanced devices.

Achieving high precision in electronic injection molding is essential for producing reliable, functional, and durable electronic components. A skilled mold maker plays a crucial role in ensuring the accuracy of each part. Through careful design, advanced techniques, and the use of high-quality materials, high-precision molding can meet the strict demands of the electronics industry.