Automotive injection molds shape plastic components used in vehicles. These molds create precise, durable, and lightweight parts. Every vehicle contains molded plastic components. High-quality molds ensure efficiency in production. A skilled mold maker ensures every part meets strict industry standards.

Why Automotive Injection Molds Are Essential

Automotive injection molds improve production speed. They ensure consistency in mass manufacturing. Molds allow for high precision. Every part must meet exact specifications. A defect can lead to assembly line delays. A reliable mold maker prevents such issues.

Key Automotive Parts Made with Injection Molds

1. Interior Components

These include dashboards, door panels, and consoles. They require a smooth finish and precise fitting.

2. Exterior Components

Bumpers, grilles, and fenders are made using automotive injection molds. These parts must be durable and impact-resistant.

3. Under-the-Hood Parts

Molds create fluid reservoirs, battery casings, and air ducts. These components must withstand heat and chemicals.

4. Lighting Components

Headlights, taillights, and indicator housings come from molds. They must be clear and heat-resistant.

How a Mold Maker Ensures Quality

A mold maker follows strict steps to create high-quality molds. Each step ensures precision and durability.

1. Design and Engineering

Engineers use 3D modeling software. The design must be perfect before production.

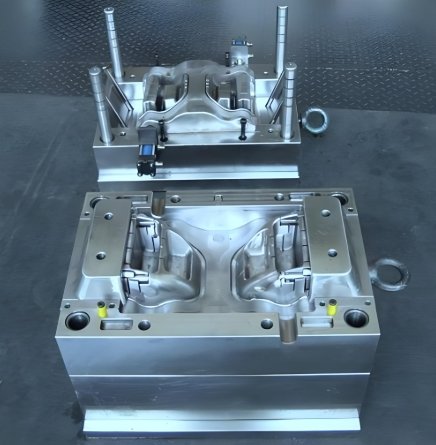

2. Material Selection

A mold maker chooses the right material. Steel molds last longer. Aluminum molds are cost-effective for short runs.

3. CNC Machining

Machines cut and shape the mold. Precision ensures accurate part dimensions.

4. Heat Treatment

This strengthens the mold. It increases durability and lifespan.

5. Polishing and Assembly

The mold is polished for a smooth finish. Every part is assembled with precision.

6. Testing and Quality Control

The mold is tested before mass production. Any defects are corrected.

Types of Automotive Injection Molds

1. Single-Cavity Molds

These molds create one part at a time. They are used for large components.

2. Multi-Cavity Molds

These produce multiple parts at once. They improve efficiency and reduce costs.

3. Hot Runner Molds

These molds reduce material waste. They improve cycle time and part quality.

4. Cold Runner Molds

These molds are cost-effective. They work well for simpler designs.

Challenges in Automotive Injection Molding

1. High Precision Requirements

Every mold must be exact. Even small errors cause defects.

2. Material Costs

High-quality steel and aluminum are expensive. A mold maker must balance cost and durability.

3. Long Production Times

Making a mold takes time. Every step requires precision.

4. Maintaining Consistency

Each mold must produce identical parts. Any variation can cause defects.

Innovations in Automotive Injection Molds

1. 3D Printing for Prototyping

3D printing speeds up the design process. It allows quick testing before full production.

2. Advanced CNC Machining

Faster cutting tools improve mold accuracy. Automation enhances precision.

3. Automation in Mold Making

Robots improve efficiency. They reduce human errors in production.

4. Sustainable Mold Materials

Recyclable materials reduce waste. They make molding more eco-friendly.

The Role of Injection Molds in Assembly Lines

1. Faster Production

Automotive injection molds speed up assembly lines. They allow quick and efficient part production.

2. Cost Efficiency

Molds reduce labor costs. They allow mass production with minimal waste.

3. Improved Part Quality

Precision molds ensure high-quality parts. This reduces defects and recalls.

4. Customization for Different Models

Molds can be adjusted for different car models. This allows flexibility in production.

The Future of Mold Makers in Automotive Manufacturing

The demand for automotive injection molds is growing. Electric vehicles require new mold designs. Lightweight materials are becoming more popular. Automation is transforming mold making. A skilled mold maker must stay updated with new technologies.

Automotive injection molds are essential in vehicle production. They improve efficiency and precision in assembly lines. A skilled mold maker ensures durability and accuracy. Innovations continue to shape the industry. The future of automotive injection molds looks promising.