Advanced Driver Assistance Systems (ADAS) improve vehicle safety. These systems use cameras, sensors, and control units. Automotive injection molds create precise plastic components for ADAS. A skilled mold maker ensures accuracy in every part.

Why ADAS Needs High-Quality Injection Molds

ADAS parts must be accurate. Even small errors affect performance. Automotive injection molds ensure precise manufacturing. A reliable mold maker helps maintain strict quality standards.

Key ADAS Components Made with Injection Molding

1. Camera Housings

Cameras monitor traffic, lanes, and obstacles. Their housings must be durable and lightweight. Automotive injection molds create strong, heat-resistant enclosures.

2. Radar Covers

Radar sensors detect vehicles and objects. Their covers protect sensitive electronics. A skilled mold maker ensures a perfect fit.

3. Sensor Mounts

Sensors track speed, distance, and movement. Strong mounts prevent vibration. Injection molding ensures secure placement.

4. Control Module Casings

ADAS modules process data. Their casings protect circuits from heat and moisture. Automotive injection molds create durable enclosures.

5. Display Panels

ADAS displays show real-time data. Injection-molded plastic creates clear, durable screens. A mold maker ensures precision.

Benefits of Injection Molding for ADAS

1. High Precision

ADAS requires accurate components. Injection molding ensures exact dimensions.

2. Lightweight Parts

Plastic reduces overall vehicle weight. Lighter cars improve fuel efficiency.

3. Cost-Effective Manufacturing

Mass production lowers costs. Automotive injection molds ensure efficiency.

4. Heat and Impact Resistance

ADAS parts face extreme conditions. Injection-molded materials withstand heat and impact.

5. Consistency in Production

Every part meets the same standards. This ensures reliability and safety.

The Role of a Mold Maker in ADAS Development

A mold maker plays a key role in ADAS production. They design, test, and refine molds for high precision.

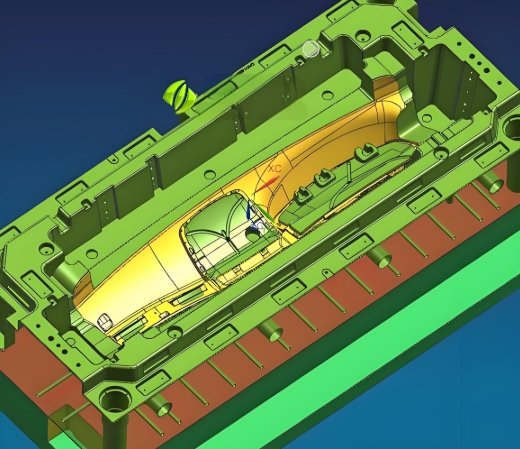

1. Designing the Mold

Engineers create 3D models. The design must match ADAS component requirements.

2. Choosing the Right Material

High-performance plastics improve durability. A mold maker selects the best option.

3. CNC Machining for Accuracy

CNC machines cut molds with extreme precision. Every part fits perfectly.

4. Testing for Quality

Molds go through strict testing. This ensures flawless performance.

Different Types of Injection Molds for ADAS

1. Single-Cavity Molds

These molds create one part at a time. They ensure high precision.

2. Multi-Cavity Molds

These molds produce multiple parts in one cycle. They improve efficiency.

3. Hot Runner Molds

These molds reduce waste. They speed up production.

4. Overmolding

This process combines multiple materials. It enhances durability.

5. Insert Molding

Plastic is molded around metal inserts. This strengthens the part.

Challenges in ADAS Mold Manufacturing

1. Complex Designs

ADAS components have intricate shapes. A skilled mold maker ensures precision.

2. Material Selection

Different plastics offer different properties. Choosing the right material is critical.

3. Strict Safety Standards

ADAS must meet high industry standards. Even small defects can cause failure.

4. Cost Management

Custom molds require investment. However, they reduce long-term costs.

5. Rapid Technological Changes

ADAS technology evolves quickly. Mold makers must adapt to new designs.

Innovations in Injection Molding for ADAS

1. 3D Printing for Prototyping

Rapid prototyping speeds up development. Engineers test new designs quickly.

2. AI-Powered Mold Design

Artificial intelligence optimizes mold geometry. This improves efficiency.

3. Sustainable Materials

Eco-friendly plastics reduce environmental impact. The industry moves toward greener solutions.

4. Automation in Manufacturing

Robotic systems increase accuracy. They reduce human error.

How Injection Molding Improves ADAS Production

1. Faster Production Cycles

Injection molding allows rapid part creation. This speeds up ADAS manufacturing.

2. Higher Quality Standards

Every part meets exact specifications. This ensures consistency.

3. Cost Savings in Mass Production

Custom molds may be expensive upfront. However, they reduce costs in large-scale manufacturing.

4. Improved Vehicle Performance

Lightweight and durable parts enhance efficiency. Vehicles become safer and more reliable.

Future of Injection Molding in ADAS

Custom automotive injection molds continue to evolve. Electric and autonomous vehicles require advanced molding techniques. A skilled mold maker plays a key role in future developments. The demand for precision and innovation grows every year.

Automotive injection molds shape the future of ADAS. They ensure precision, durability, and efficiency. A professional mold maker designs molds that meet exact automotive standards. As technology advances, injection molding will play an even bigger role in ADAS development.