A customer from Russia came to our injection mould company with a small plastic part in his hand. He explained that the part was made using a 3D printer, Now he wanted to get helps from a mold maker but it had some problems. The customer wanted us to help him make a better version of this part and then start producing it in large numbers.

Our team discussed the problems with the customer, explaining how the injection molds process works differently from 3D printing. We told him that with injection molds, we could make the part much smoother, stronger, and more accurate. The customer was happy to hear that we could fix the issues and produce a high-quality part.

Our team discussed the problems with the customer, explaining how the injection molds process works differently from 3D printing. We told him that with injection molds, we could make the part much smoother, stronger, and more accurate. The customer was happy to hear that we could fix the issues and produce a high-quality part.

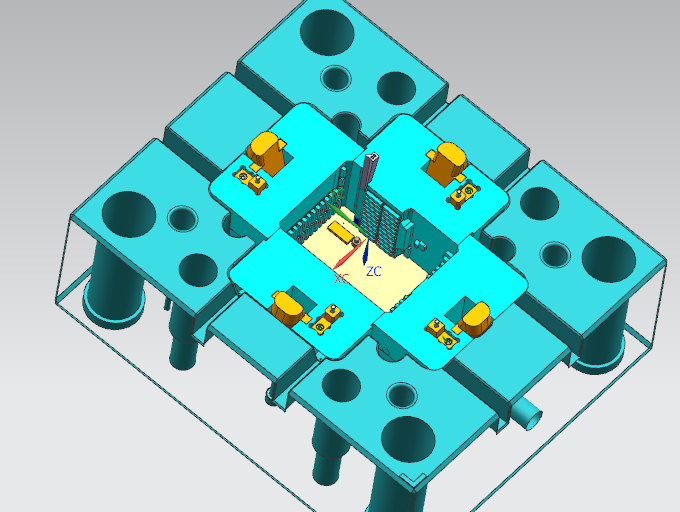

The next step was to design a mold that would correct the problems in the sample. Our engineers carefully measured the 3D-printed part and used computer software to design a mold that would make the part perfectly. We made sure the edges would be smooth and that all the dimensions were exact. This is something that an injection mold china specialist, like our company, is very good at doing.

Once the design was ready, we started making the mold. This is a very important step because the mold has to be perfect. If there’s a mistake in the mold, every part that comes out of it will have the same mistake. As a trusted mold maker, we took our time to make sure the mold was just right.

After the mold was finished, we tested it by producing a few sample parts. We checked these parts carefully to make sure they were exactly what the customer wanted. The edges were smooth, the dimensions were perfect, and the material was strong and durable. The customer was very pleased with the results.

With everything ready, we moved on to the production phase. At our injection moulding factory, we can produce large numbers of parts very quickly using the molds we make. We set up the mold in our machine and started producing the parts. The customer from Russia was happy to see the first batch of parts coming out just as he had hoped.

This story shows how our injection mould company can help customers solve problems with their designs. Whether it’s fixing issues in a 3D-printed sample or producing large quantities of high-quality parts, we have the experience and skills to get the job done. As a leading mold maker in the industry, we take pride in helping customers from all over the world, including Russia, achieve their goals with the best injection molds and production processes available.