Medical products are crucial in healthcare. Many of them use plastic components made with injection molding. This method helps produce items like syringes, tubing, and surgical tools. Here are four important points to know about medical product plastic molds. Each point covers why these molds matter in healthcare and how they are made. Mold makers and injection mould companies play key roles in the process.

1. Sterilization Is Vital

Medical products need to be clean. In fact, they must be sterile to prevent infections. Mold makers design molds that can handle tough sterilization processes. This is because molds must withstand heat, chemicals, or steam.

Plastic materials must also survive these harsh treatments. A good injection mould company will choose materials that hold up well. This includes materials like stainless steel or medical-grade plastic. Proper sterilization ensures the safety of patients.

2. Precision in Medical Molding

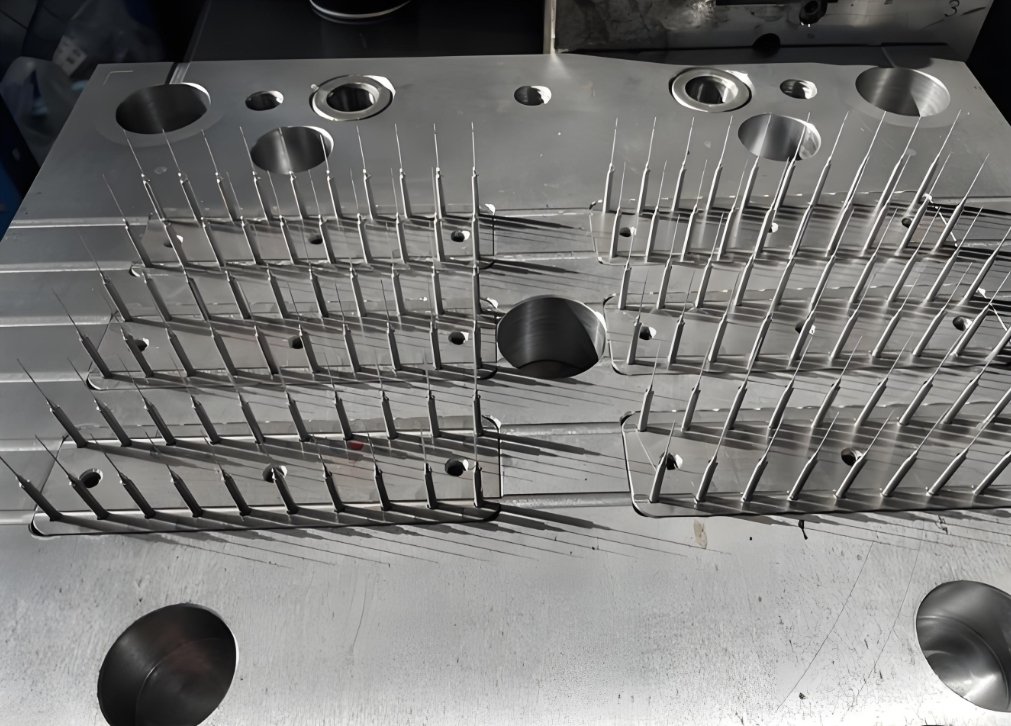

Accuracy is a top priority in medical products. Small mistakes in size or shape can cause big problems. That’s why precision is key in injection molding. Mold makers use special machines to make sure the parts fit perfectly.

Every medical product must pass strict tests. Medical devices like implants or syringes must work flawlessly. Injection molding makes it easier to mass-produce these precise parts. When you need accuracy, an experienced injection mould company is a must.

3. Choosing the Right Plastic Materials

Not all plastics work for medical devices. Medical products often need special materials that are safe for the human body. This means that the plastic used must not cause any allergic reactions or infections.

Mold makers carefully pick materials that fit the product’s needs. For example, polypropylene is used for products like syringes. It’s flexible, strong, and resistant to chemicals. In some cases, medical products require more expensive, biocompatible plastics. Choosing the right material makes all the difference.

4. Following Strict Industry Standards

Medical products must meet many regulations. These rules keep patients safe. Mold makers and injection mould companies must stay up-to-date with changes in these rules. They must make sure their products meet all required standards.

One of these standards is ISO 13485. It ensures that medical devices are made with quality in mind. Mold makers must follow strict steps during production. Any mistake can delay the product’s release or even stop it from being used in hospitals.

5. Prototyping and Testing Are Key

Before making a mold, testing is essential. Prototypes allow companies to test the design. This ensures the product works as intended. It helps find any mistakes before mass production starts.

Working with an injection mould company during this phase is important. Mold makers can spot errors early. This saves time and money. Testing ensures that the mold produces high-quality products. The last thing you want is to waste resources due to faulty designs.

Why You Need an Expert Mold Maker

A professional mold maker is vital in the medical field. Mold makers ensure the mold is designed to the highest standard. They make sure it meets all the rules and can handle tough sterilization methods. Without expert guidance, the final product may not meet industry standards.

For your next medical product, work with an injection mould company that understands the industry. Popper Mold-Tech offers precision, safety, and compliance. We help design and create molds that meet all medical regulations. With years of experience, our team knows how to bring your medical product to life.

In General

Medical product plastic molds are essential for healthcare. They help make safe, precise, and effective devices. Mold makers and injection mould companies play a big role in ensuring quality and safety. By focusing on sterilization, precision, material selection, and regulations, companies can make top-notch medical products.

Remember, it’s crucial to work with professionals who know the industry. Injection molding is a specialized field, especially in healthcare. If you need high-quality molds, choose experts who can deliver the best results.