Show Cases

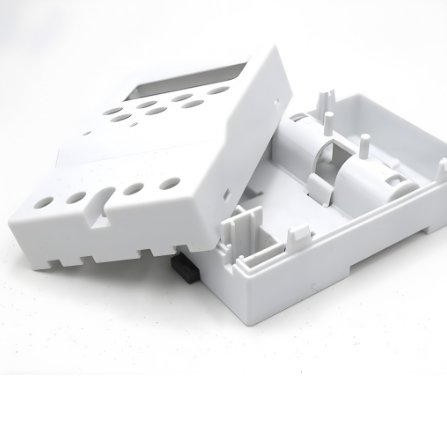

In Electronic Injection Molding, every product is different.Every design has its own challenges.Some...

In Electronic Injection Molding, temperature matters.It affects flow, cooling, shrinkage, and...

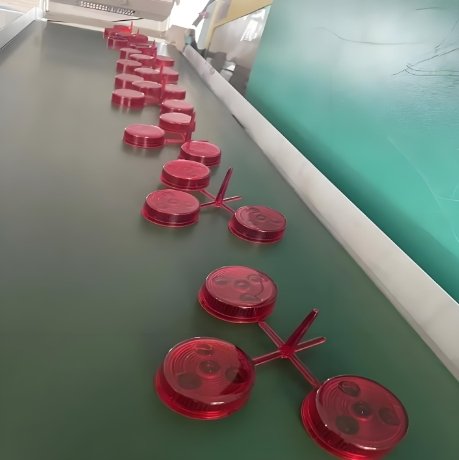

In Electronic Injection Molding, every choice matters.Runner systems are one of the most important...

In Electronic Injection Molding, temperature matters.A lot. Every mold must stay at the right...

In Electronic Injection Molding, molds endure a lot of stress. The pressure, temperature, and...

In Electronic Injection Molding, the choice of runner system is critical. Runners guide the molten...

Choosing the right tooling material is critical in Electronic Injection Molding. A skilled Mold...

In Electronic Injection Molding, the quality of the final product is largely determined by the...

In Electronic Injection Molding, accuracy is everything. Parts must fit perfectly. Small errors can...

In Electronic Injection Molding, dimensional stability is key. Electronic parts must fit precisely...