Soft-touch overmolding is becoming a big trend in the electronics world. Customers today want products that not only work well but also feel good in their hands. Devices with smooth, rubbery surfaces are easier to grip, more comfortable to use, and look more stylish. To make this happen, companies turn to Electronic Injection Molding and expert Mold Maker skills.

This article will explain why soft-touch overmolding is growing fast, how it works, and what it means for the future of electronics.

What is Soft-Touch Overmolding?

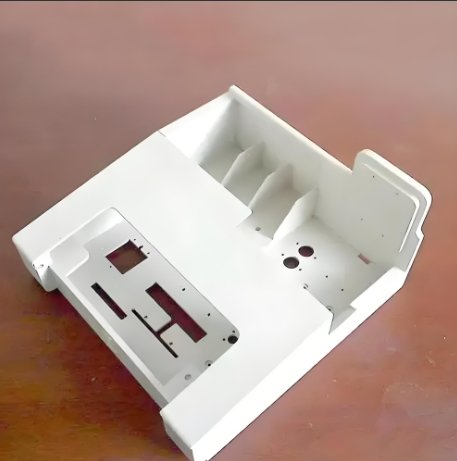

Soft-touch overmolding is a process where a soft, flexible material is molded over a hard plastic or metal part. This gives the final product a soft, rubber-like surface. In Electronic Injection Molding, this process adds both beauty and function to a device.

Common materials used for soft-touch layers include:

- Thermoplastic elastomers (TPE)

- Thermoplastic polyurethane (TPU)

- Silicone rubber

These materials feel soft but are also tough and durable. A skilled Mold Maker designs molds that allow these materials to bond perfectly to the hard substrate.

Why Electronics Need Soft-Touch Overmolding

There are many reasons why electronics companies love soft-touch overmolding:

1. Better Grip

Devices like smartphones, remote controls, or game controllers must not slip out of users’ hands. Soft-touch surfaces provide a safer, more comfortable grip.

2. Enhanced Appearance

Soft-touch parts look sleek and premium. A nice surface feel can make an ordinary product seem high-end.

3. Shock Protection

Soft coatings help absorb impacts. This can protect sensitive electronics inside from drops or bumps.

4. Weather and Chemical Resistance

Many overmolded materials resist water, oils, and other chemicals. This adds durability and reliability to electronic products.

5. Design Flexibility

Overmolding lets designers add color accents, logos, and unique textures easily. This helps products stand out in a crowded market.

The Electronic Injection Molding process, when handled by an experienced Mold Maker, ensures these benefits are fully realized.

How Soft-Touch Overmolding Works

Soft-touch overmolding usually happens in two stages:

- First Shot: The hard part (often ABS, PC, or metal) is molded.

- Second Shot: A soft material (like TPE) is molded over specific areas of the first part.

This can happen using two different molds (two-shot molding) or in the same mold with clever design. The Mold Maker must plan carefully to make sure the two materials bond well and stay in place.

Important factors include:

- Proper surface preparation

- Temperature control for each material

- Precise alignment during the second shot

- Good material compatibility

When these factors are managed right, the result is a strong, beautiful, soft-touch part that performs better and lasts longer.

Challenges in Soft-Touch Overmolding

Even with the best Electronic Injection Molding machines, soft-touch overmolding is tricky. Some common challenges include:

- Poor adhesion: If the soft material doesn’t stick well, it can peel off during use.

- Warpage: Different shrink rates between materials can cause the part to bend or twist.

- Material bleeding: Soft material may spread into areas where it’s not wanted.

- Longer cycle times: Two-shot molding takes more time and careful control.

This is where the skills of a great Mold Maker come in. With good mold design and smart processing, these risks can be reduced or eliminated.

Applications of Soft-Touch Overmolding in Electronics

Soft-touch overmolding is popular across many electronic products, such as:

- Smartphones: Side grips and button covers

- Wearable Devices: Fitness trackers and smartwatches

- Remote Controls: Comfortable grips and rubberized buttons

- Game Controllers: Enhanced grips and shock protection

- Medical Electronics: Handheld scanners and monitors

- Industrial Controls: Ruggedized keypads and handheld units

In each case, soft-touch surfaces improve both how the device feels and how it performs. High-quality Electronic Injection Molding, backed by expert Mold Maker work, ensures that companies deliver top-notch products.

The Role of the Mold Maker in Soft-Touch Overmolding

The Mold Maker has a huge role in successful soft-touch overmolding. They must:

- Design molds that allow perfect bonding between materials

- Choose correct materials for compatibility and performance

- Ensure exact placement of soft and hard materials

- Minimize waste and reduce cycle times

- Test thoroughly to prevent defects

In Electronic Injection Molding, mistakes can be costly. A tiny error in mold design can mean peeling layers, bad fits, or product recalls. That’s why choosing an experienced Mold Maker is so important for companies entering the soft-touch market.

Future Trends in Soft-Touch Overmolding for Electronics

Soft-touch overmolding will continue growing fast, driven by user demand and design innovation. Some exciting trends include:

- Eco-Friendly Materials: New soft-touch materials made from recycled or bio-based plastics.

- Antimicrobial Coatings: Soft surfaces that kill germs, perfect for healthcare devices.

- Multi-Material Overmolding: Combining several materials for even better performance and design.

- Smarter Mold Designs: Using sensors and AI to make molding faster, better, and more efficient.

Top Mold Makers will stay ahead by learning new skills, investing in new technologies, and helping companies bring better products to market through high-quality Electronic Injection Molding.

Soft-touch overmolding is no longer just a luxury—it’s a key feature in modern electronics. From better grip to shock protection, from sleek designs to longer product life, the advantages are too good to ignore.

Behind every great soft-touch product is expert Electronic Injection Molding and a skilled Mold Maker. Together, they turn complex ideas into real, reliable, and beautiful devices that people love to use.

As electronics keep evolving, the demand for soft-touch overmolding will only grow. Companies that invest in quality molds and materials today will lead the market tomorrow. In the world of Electronic Injection Molding, the future definitely feels soft—and strong.