Developing a Minimum Viable Product (MVP) is crucial for startups and innovators. It tests ideas quickly and cost-effectively. Rapid Prototyping makes this possible. Partnering with an Injection Mould Company ensures high-quality results. This article explores how Rapid Prototyping simplifies MVP creation.

What is an MVP?

An MVP is the simplest version of a product. It includes only the core features. MVPs validate ideas with minimal resources. They gather feedback from users early.

Why Use Rapid Prototyping for MVPs?

Speeds Up Development

Time matters when launching an MVP. Rapid Prototyping shortens development cycles. Designers create models faster. This leads to quicker iterations.

Reduces Costs

Traditional methods are expensive. Rapid Prototyping cuts costs by using less material. An Injection Mould Company optimizes designs for affordability.

Enhances User Feedback

Prototypes let users experience the product early. This ensures feedback is accurate and relevant. Designers can make improvements before final production.

Challenges in MVP Development

Limited Resources

Startups often lack funds and equipment. Prototyping costs can be overwhelming.

Solution

Work with an Injection Mould Company. They provide affordable solutions.

Design Complexity

Some MVPs require intricate designs. This complicates the prototyping process.

Solution

Simplify designs. Use Rapid Prototyping to test each feature separately.

Tight Deadlines

MVPs must launch quickly to stay competitive.

Solution

Leverage Rapid Prototyping technologies like 3D printing and CNC machining.

Role of an Injection Mould Company

Material Selection

They recommend suitable materials for prototypes. This ensures durability and functionality.

Design Refinement

Their engineers optimize designs for manufacturability. This reduces errors and costs.

Transition to Production

They help scale MVPs into full products. This streamlines the entire process.

How Rapid Prototyping Enhances MVP Creation

Iterative Testing

Prototypes allow repeated testing. Each iteration improves the product. Feedback is applied quickly.

Functional Validation

Prototypes validate the product’s functionality. Designers identify flaws early.

Market Fit

Prototypes test market responses. Businesses refine MVPs to match user needs.

Tools for Rapid Prototyping

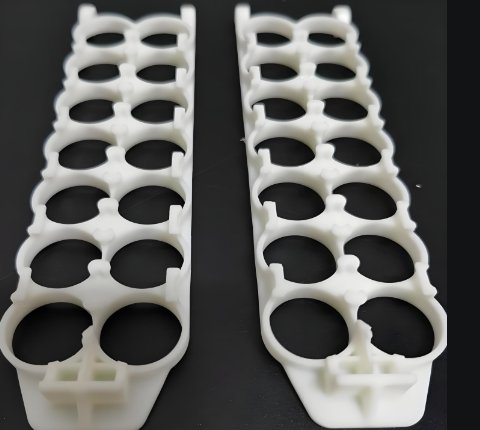

3D Printing

Perfect for creating intricate designs. It’s fast and cost-effective.

CNC Machining

Best for durable prototypes. It uses robust materials.

Injection Molding

Ideal for detailed MVPs. An Injection Mould Company excels in this area.

Industries Benefiting from MVP Prototypes

Consumer Electronics

Startups test devices like wearables. Rapid Prototyping speeds up the process.

Medical Devices

MVPs validate safety and functionality. Prototypes ensure compliance with standards.

Automotive

Prototypes test design and performance. This prevents costly mistakes.

Real-World Success Stories

A Wearable Tech Startup

A small company created a fitness tracker MVP. Rapid Prototyping reduced development time. Feedback improved the final product.

A Medical Innovation Firm

They needed a prosthetic limb prototype. Partnering with an Injection Mould Company ensured biocompatibility and precision.

Steps to Build an MVP with Rapid Prototyping

- Define Core Features

Focus on the product’s main purpose. - Choose Prototyping Methods

Select between 3D printing, CNC machining, or injection molding. - Test Early and Often

Gather feedback from target users. - Collaborate with Experts

Partner with an experienced Injection Mould Company.

Rapid Prototyping is essential for MVP development. It speeds up design and reduces costs. An Injection Mould Company plays a crucial role. They provide expertise and resources for high-quality prototypes. With Rapid Prototyping, businesses launch better products faster.